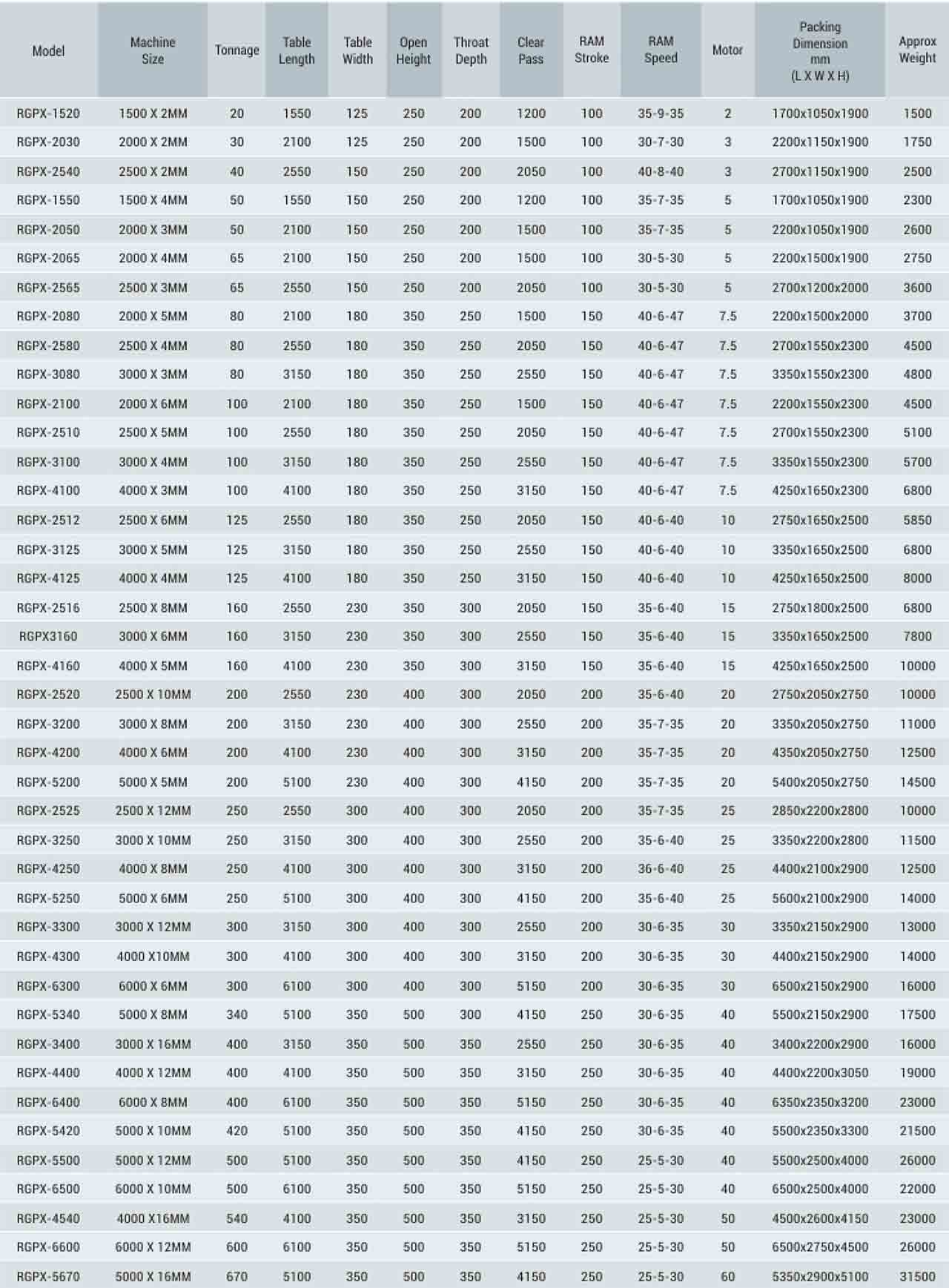

RG-PX

Hydraulic Press Brake Machine

Advantages

Standard Equipments

Optional Equipment

RGPX 2565 Hydraulic Press brake machine Video

Related Post

FAQs

What is a hydraulic press brake machine?

Metal is bent and folded by pressing it into a die using hydraulic press brakes. These presses can be used for applications requiring both continuous production and specialized sheet metal work.

What are the benefits of a hydraulic press brake machine?

- low initial expense

- low cost of toolkits

- Simple and quick setting

- extreme adaptability

- Simple to sustain

Mention the standard feature of the hydraulic press brake machine?

The following accessories and standards are included with hydraulic press brakes:

- Ram & BED

- Lubrication system

- Clutch and brake

- Drive system

- Ram adjustment mechanism

What Is the Workflow of a Hydraulic Press Brake?

Using the force of a hydraulic motor, a hydraulic press brake applies pressure to the metal, compressing it into the die to create the desired shape. The shape that the metal will take after being bent depends on the shape of the die.

Why Use a Hydraulic Press brake machine?

When looking for efficient bending processes to perform automated bending processes, many manufacturers choose hydraulic press brakes.