Blog

Hydraulic Press Brake Machines

Contents

- 1 Revolutionizing Metal Fabrication: The Hydraulic Press Brake Machines by Rajesh Machine Tools Pvt. Ltd.

- 2 Technical Specification

- 3 A Fusion of Strength and Precision

- 4 Intelligent Control for Unmatched Versatility

- 5 Enhanced Safety and Convenience

- 6 Fine Tuning Your Craft

- 7 Precision Back Gauge for Accurate Bending

- 8 Durability Meets Efficiency

- 9 Maintenance Made Easy

- 10 Optimized Ram Alignment

- 11 Trusted Components for Reliable Performance

- 12 Conclusion

Revolutionizing Metal Fabrication: The Hydraulic Press Brake Machines by Rajesh Machine Tools Pvt. Ltd.

In the dynamic world of metal fabrication, efficiency and precision are paramount. Rajesh Machine Tools Pvt. Ltd., a trailblazer in the manufacturing sector, presents its cutting-edge Hydraulic Press Brake Machines. This machine is not just a piece of equipment; it’s a game-changer for businesses seeking to enhance their metal-bending processes.

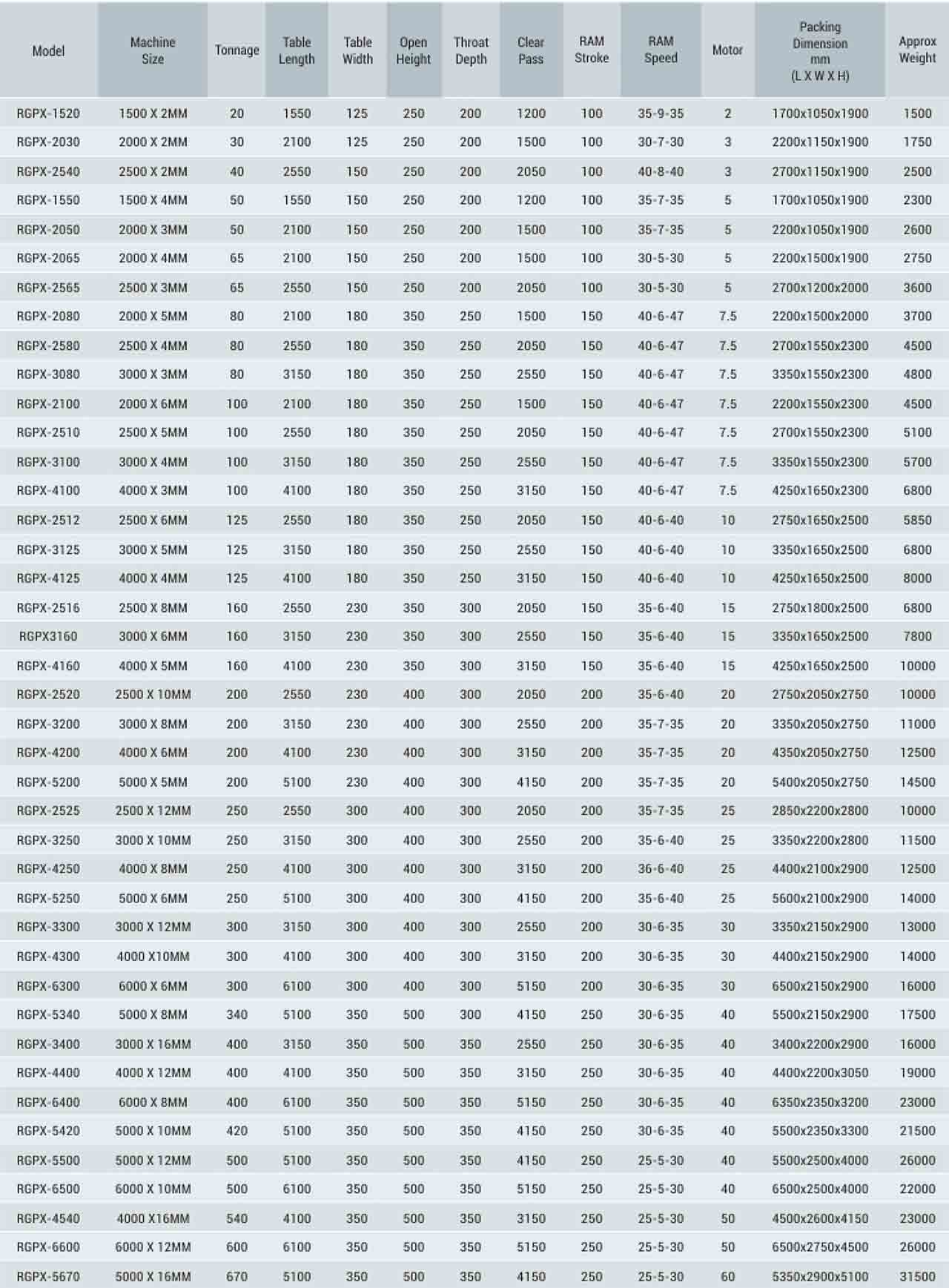

Technical Specification

A Fusion of Strength and Precision

At the heart of these machines is a robust welded steel frame structure. This foundation ensures durability and stability, crucial for precision metalworking. The compact cylinder design, an innovative approach, reduces the need for high pressure, thanks to the rear cylinder system. It’s a testament to engineering ingenuity, balancing power with finesse.

Intelligent Control for Unmatched Versatility

The electrical control panel is a core feature, equipped with multiple mode selections, including inch, single cycle, and auto mode operations. This versatility allows for adaptability to various project requirements, making it a valuable asset for diverse metalworking tasks.

Enhanced Safety and Convenience

Safety in operation is paramount. The inclusion of a mobile pair of foot switch panels emphasizes this, providing operators with control and mobility. Additionally, the front sheet support, extending 600 mm in length, ensures ease of handling materials, a critical factor in maintaining precision in metal bending.

Fine Tuning Your Craft

Precision is in the details. The adjustment rod with a limit switch, provided for fine stroke adjustments, speaks volumes about the attention to detail in the design. This feature allows for minute adjustments, ensuring every bend meets exact specifications.

Precision Back Gauge for Accurate Bending

The front-operated manual back gauge, fitted with a lead screw, is another highlight. This feature enables accurate measurement and positioning of the metal sheet, ensuring consistent bending angles, a crucial factor for quality and repeatability in production.

Durability Meets Efficiency

Durability is non-negotiable. The standard 5 “V” die, made of EN-8 material, and the punch made of EN-31 (both unhardened) are designed to withstand the rigours of metal bending. This durability ensures long-term efficiency and reduces the need for frequent replacements.

Maintenance Made Easy

We’ve thoughtfully added the centralized lubrication system. It simplifies maintenance, ensuring proper lubrication for all moving parts, reducing wear, and extending the machine’s lifespan.

Optimized Ram Alignment

The ram tilting arrangement, located on the outer right side of the machine, enhances the machine’s flexibility. This feature allows for adjustments in the ram alignment, crucial for achieving precise bending angles.

Trusted Components for Reliable Performance

Reliability is key. All electric and hydraulic components are made up of reputed makes, ensuring quality and reliability. This commitment to using top-tier components means fewer breakdowns and a smoother, more reliable operation.

Conclusion

The Hydraulic Press Brake Machines by Rajesh Machine Tools Pvt. Ltd. are more than just equipment. They are a commitment to excellence, a blend of robust design, advanced technology, and user-friendly features. These machines are tailored for businesses that value precision, efficiency, and reliability in metal fabrication.

Embrace the future of metal bending with Rajesh Machine Tools Pvt. Ltd. – where innovation meets craftsmanship. Visit the RG-PX Hydraulic Press Brake Machine to explore the world of possibilities these machines offer.

Read About: Hydraulic Shearing Machines

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.