RG – Plus+

(CNC Press Brake Machine)

At Rajesh Group we are manufacturing CNC Press Brake Machines. Our Press Brake Machines are CNC control operated. These CNC Press Brake Machines are highly accurate and easy to operate and as well as easy to maintain and long lasting.

Our CNC Press Brake Machines are high quality with highly accurate in operations. These Press Brake Machines are far more advanced than regular Sheet Metal Bending Machines.

Advantages

Standard Equipments

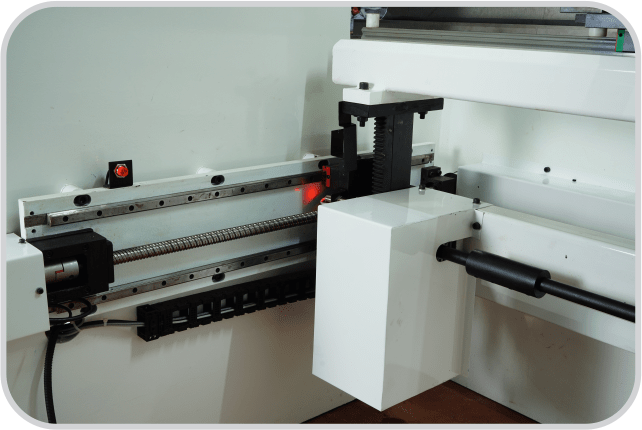

Adjustment

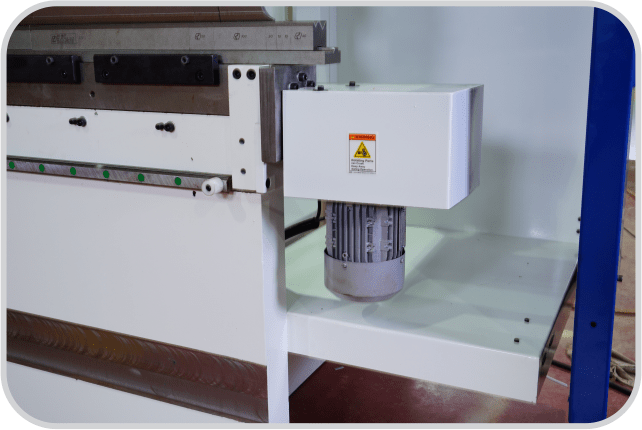

Motor

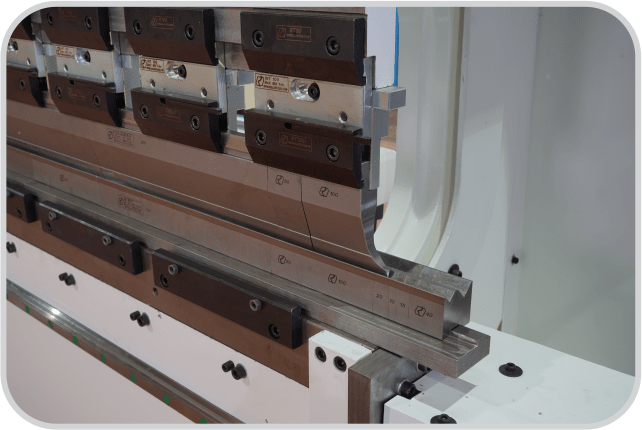

V Groove

Bending Adjustment

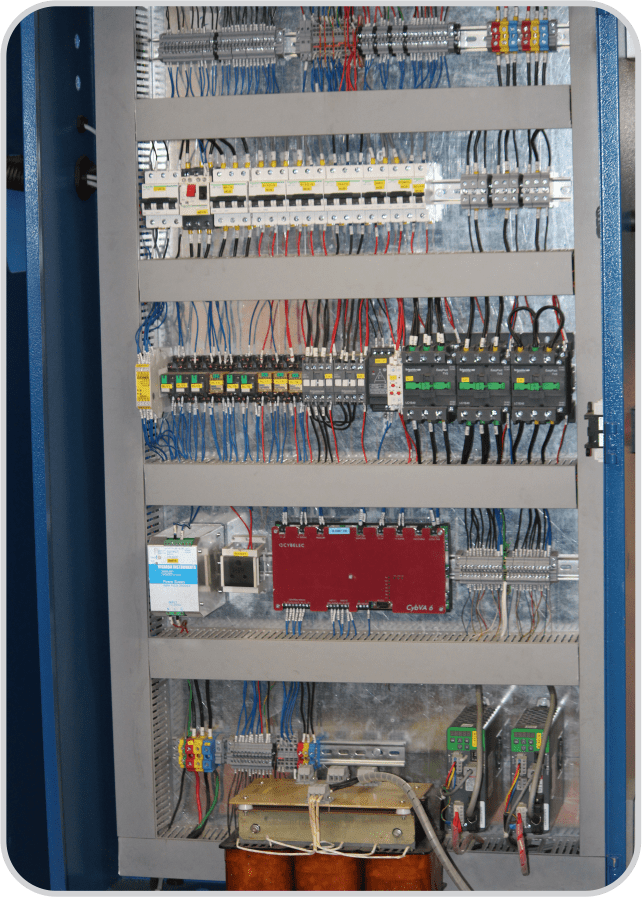

Electric Panel

FAQs

What is a CNC Press Brake Machine?

CNC Press Brake Machine is useful for bending sheet metal and sheet metal components into different shapes and profiles.

How does the CNC Press Brake Machine Work?

Hydraulic or electrical force is used to run the machine. it depends on your machine’s type.

What are the features of a CNC press brake machine?

CNC press brake machines come with various types of features and characteristics. Here we mention the standard features of CNC press brake machines.

- It offers the CNC DELEM DA53T system that supports 2D graphics (colour)

- It has dual beam photocells from Lazer Safe

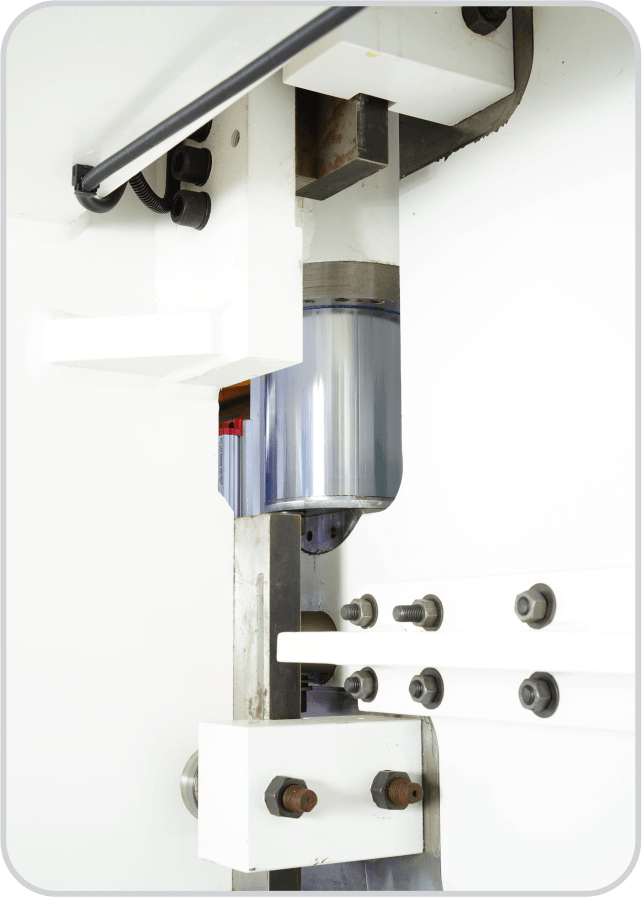

- It consists of a hydraulic system from Hoerbiger

- It consists of optical scales from GIVI

- It offers the class IE3 motor which is known for its high efficiency

- It has Accurl’s very own wave crowning system (Accurl Pro)

- It consists of an electrical cabinet made with Siemens and Schnider parts

What is the price of a CNC press brake machine?

In India, the average market price of a CNC press brake is Rs 14 Lakh per unit.

What is the importance of a CNC Press Brake Machine?

Manufacturing sectors and fabricators will not be able to grow without CNC press brake machines.

How long does it take to change the hydraulic oil in a press brake machine?

CNC press brake machines come with a number of benefits including it is easy to operate, efficient, cost-effective, and versatile.

How to operate a CNC press brake machine?

The hydraulic oil must be cleaned out of the tank and replenished or filtered after three months when the hydraulic bending machine is first put into service.

What is the working principle of hydraulic CNC Press Brake Machine?

This machine works by using two cylinders. One cylinder pushes a rotating fixed disc while the other turns a shaft.

Advantages of press brake machine?

It’s easy to use and operate.

Why use a CNC Press Brake Machine?

It has a great degree of adjustability and precision, and also uses computer technology to boost productivity and control accuracy.