Blog

Hydraulic Press Brake Machine Manufacturers in India

Contents

- 1 Leading the Way: Rajesh Machine Tools Pvt. Ltd. – Your Trusted Hydraulic Press Brake Machine Manufacturers in India

- 2 Technical Specification

- 3 Unmatched Quality and Precision

- 4 The Backbone of our Machines: Robust Welded Steel Frame

- 5 Efficient Cylinder Design: Power Meets Elegance

- 6 Tailored Control: Versatility at Your Fingertips

- 7 Enhanced Safety and Accessibility: Mobile Foot Switch Panel

- 8 Supporting Your Work: Front Sheet Support and Fine Stroke Adjustment

- 9 Precision in Motion: Front Operated Manual Back Gauge

- 10 Durability Meets Precision: Standard 5 “V” Die and Punch

- 11 Seamless Operation: Centralized Lubrication System

- 12 Enhanced Control: Ram Tilting Arrangement

- 13 Trusted Components: Reputed Electric & Hydraulic Parts

- 14 Transform Your Operations with Rajesh Machine Tools

Leading the Way: Rajesh Machine Tools Pvt. Ltd. – Your Trusted Hydraulic Press Brake Machine Manufacturers in India

When it comes to Hydraulic Press Brake Machine Manufacturers in India, Rajesh Machine Tools Pvt. Ltd. stands as a shining example of precision engineering and manufacturing excellence. With a legacy of delivering top-notch bending solutions, we have earned a reputation as one of the leading manufacturers in the industry. If you’re seeking high-quality hydraulic press brake machines, look no further than Rajesh Machine Tools Pvt. Ltd.

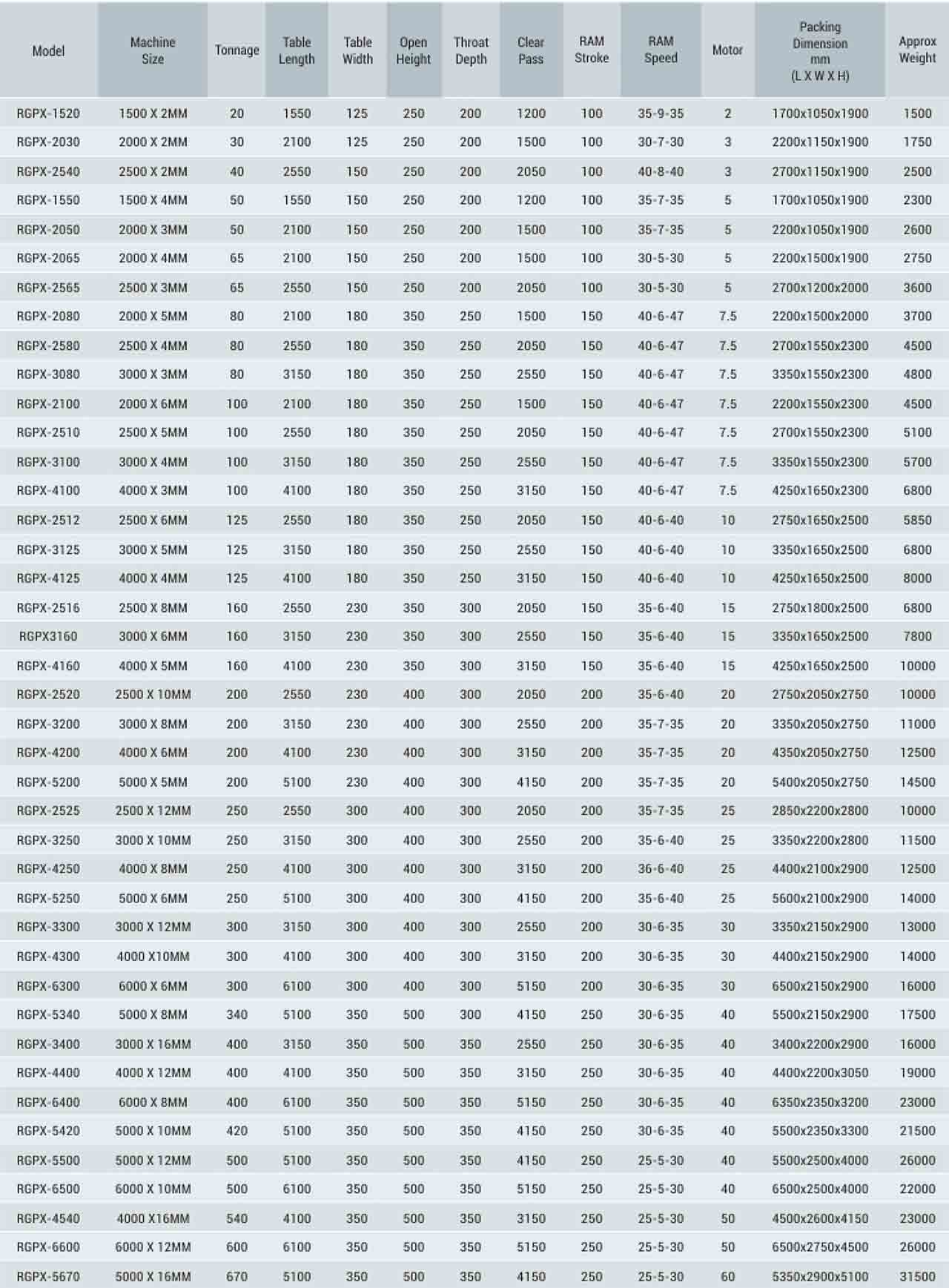

Technical Specification

Unmatched Quality and Precision

Our Hydraulic Press Brake Machines are the epitome of engineering excellence. Each machine is a testimony to robust construction and technological advancement. Our commitment to quality begins with the selection of premium materials and extends to our meticulous manufacturing process.

The Backbone of our Machines: Robust Welded Steel Frame

The foundation of our Hydraulic Press Brake Machine’s unparalleled performance is its robust welded steel frame structure. This solid foundation ensures durability and reliability, giving our customers confidence in their investment.

Efficient Cylinder Design: Power Meets Elegance

Our compact cylinder design is a marvel of engineering, requiring low pressure due to the innovative rear cylinder system. This unique approach not only enhances efficiency but also ensures smoother operation and longevity of the machine.

Tailored Control: Versatility at Your Fingertips

Our electrical control panel is designed for versatility, offering multiple mode selections including inch, single cycle, and auto mode operations. This flexibility allows for customization according to specific project requirements, making our machines a versatile tool in any workshop.

Enhanced Safety and Accessibility: Mobile Foot Switch Panel

Safety is paramount in any industrial setting, and our machines reflect this priority. The mobile pair of foot switch panels ensures safety and ease of operation, allowing the operator to maintain a safe distance and optimal control during operation.

Supporting Your Work: Front Sheet Support and Fine Stroke Adjustment

The front sheet support, extending 600 mm in length, provides stable and precise support for materials. Coupled with an adjustment rod and a limit switch for fine stroke adjustments, our machines offer unprecedented control and accuracy.

Precision in Motion: Front Operated Manual Back Gauge

The front-operated manual back gauge, fitted along with a lead screw, ensures precise and consistent bending operations. This feature enhances the machine’s capability to produce high-quality, repeatable results.

Durability Meets Precision: Standard 5 “V” Die and Punch

Our standard 5 “V” die, made of EN-8 material, and punch, crafted from EN-31 (both unhardened), represents the perfect blend of durability and precision. These high-quality components are designed to withstand rigorous use while maintaining their precision.

Seamless Operation: Centralized Lubrication System

The centralized lubrication system is a testament to our commitment to seamless operation and maintenance. This feature ensures that all critical components are consistently lubricated, reducing wear and tear and prolonging the machine’s life.

Enhanced Control: Ram Tilting Arrangement

The ram tilting arrangement, located on the outer right side of the machine, provides an additional layer of control and precision. This feature allows for fine adjustments, ensuring that every bend is as accurate as the last.

Trusted Components: Reputed Electric & Hydraulic Parts

We understand that the strength of a machine lies in the quality of its components. That’s why we use electric and hydraulic components from reputed manufacturers, ensuring reliability and performance.

Transform Your Operations with Rajesh Machine Tools

Our Hydraulic Press Brake Machines are more than just equipment; they are partners in your manufacturing journey. Embrace the power, precision, and versatility that Rajesh Machine Tools Pvt. Ltd. offers. Visit rajeshcnc.com to explore how our machines can revolutionize your metalworking operations in India. Your journey towards precision and efficiency starts here.

Read About: Mechanical Power Press Machines Manufacturer

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.