Blog

Mechanical Power Press Manufacturer

Contents

Mechanical Power Press Manufacturer

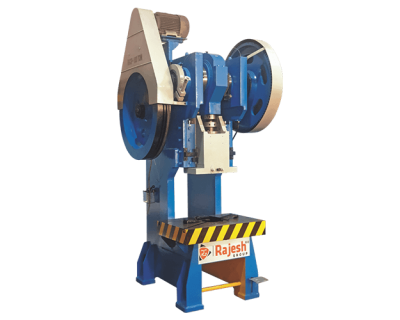

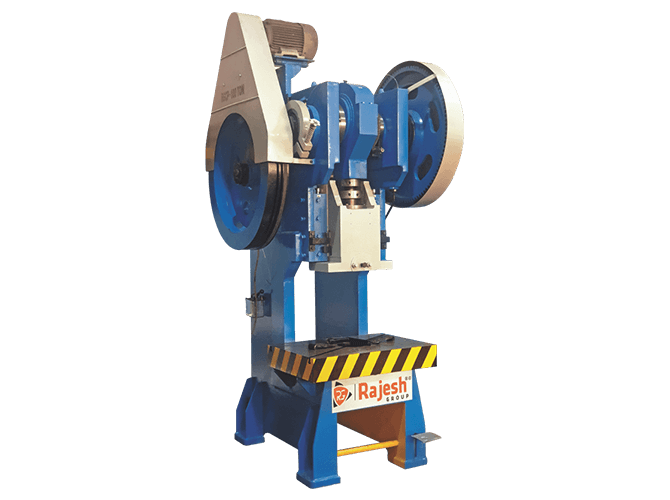

Rajesh Machine Tools Pvt. Ltd. is a famous Mechanical Power Press Manufacturer in Gujarat, India. Mechanical power presses have revolutionized the manufacturing industry with their efficiency, precision, and versatility. These robust machines play a vital role in various industries, offering a wide range of benefits to businesses. Here, we will explore the needs, benefits, and common usage of mechanical power presses.

Needs for Mechanical Power Press

- High Production Rates: Mechanical power presses excel in high-volume production environments, allowing businesses to meet demanding production targets efficiently.

- Precision and Accuracy: With their advanced automation features, mechanical power presses ensure precise and repeatable operations, maintaining consistent quality in manufacturing processes.

- Increased Efficiency: By automating repetitive tasks, mechanical power presses significantly reduce manual labour, saving time, and enhancing overall productivity.

- Versatile Applications: Industries like automotive, aerospace, and appliance manufacturing rely on mechanical power presses for punching, blanking, bending, embossing, and forming various operations.

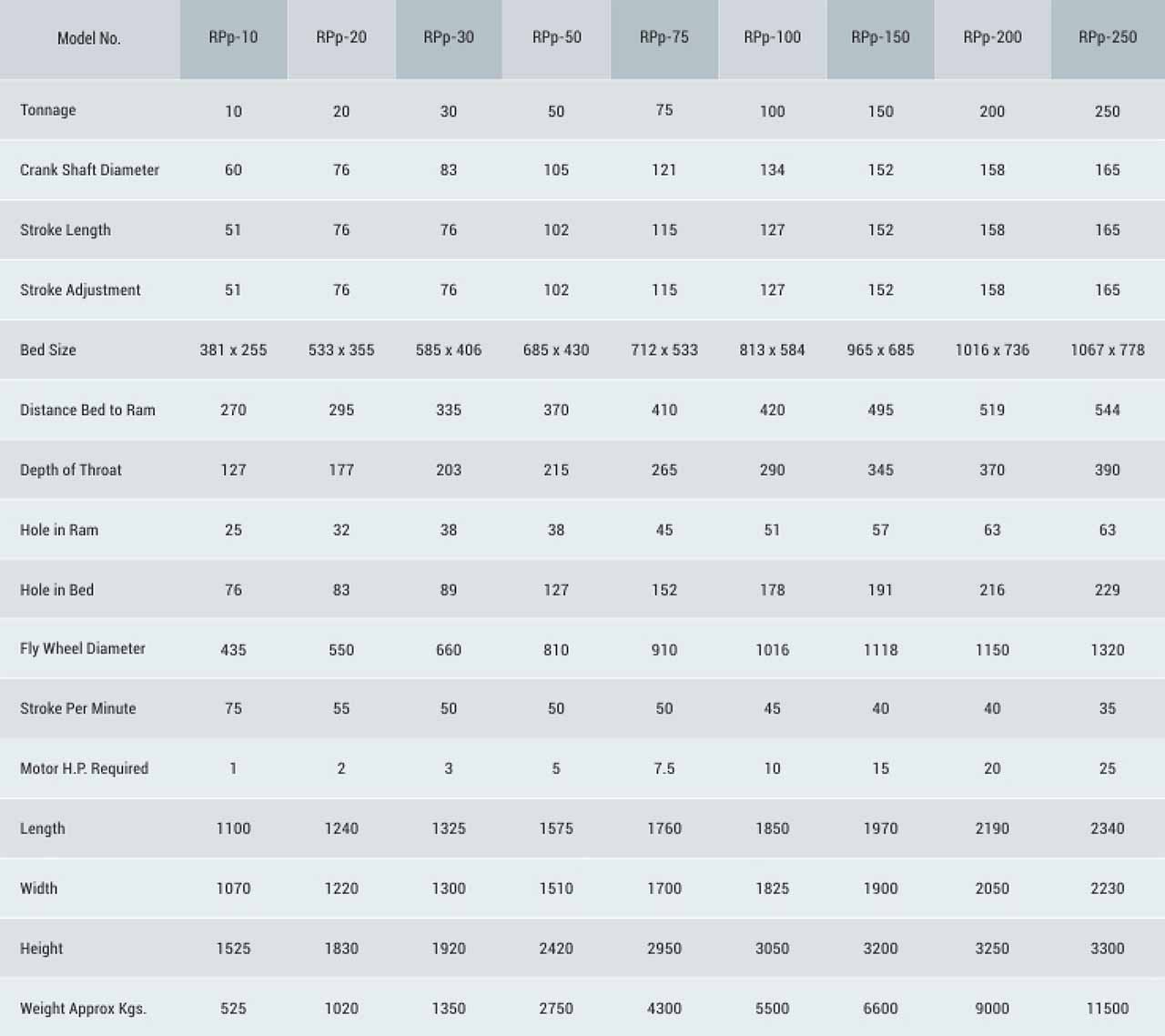

Technical Specification

Benefits of Mechanical Power Press

- Enhanced Safety: Mechanical power presses have safety features such as two-hand controls, presence-sensing devices, and emergency stops to ensure operator safety and minimize accident risks.

- Improved Productivity: Mechanical power presses boost productivity and output by streamlining processes, reducing downtime, and eliminating human error.

- Cost Savings: These machines optimize material usage, reduce scrap rates, and minimize labour costs, leading to significant cost savings for businesses in the long run.

- Consistent Quality: Mechanical power presses guarantee consistent quality, meeting industry standards and customer expectations effectively.

- Flexibility and Customization: Mechanical power presses offer diverse tooling options, enabling businesses to customize products and adapt to production changes.

Common Usage of Mechanical Power Press

- Metal Stamping: Mechanical power presses are widely used for metal stamping, creating designs, shaping components, and making precision parts.

- Automotive Industry: Mechanical power presses play a crucial role in manufacturing automotive parts, including body panels, brackets, engine components, and more.

- Appliance Manufacturing: These machines shape metal parts for home appliances such as refrigerators, washing machines, and ovens.

- Electronics Industry: Mechanical power presses produce electronic components like circuit boards, connectors, and terminals with precision in fabrication and assembly.

- Packaging and Printing: These machines shape and form metal parts that are used in producing home appliances like refrigerators, washing machines, and ovens.

Conclusion

Mechanical power presses offer a multitude of benefits, from increased productivity and cost savings to improved safety and consistent quality. Their versatility and efficiency make them indispensable in a wide range of industries. Mechanical power press tech boosts manufacturing efficiency, productivity, and competitiveness in today’s dynamic market.

Read About: NC Shearing Machine

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.