Blog

Plate Rolling Machine Brief Details

Plate Rolling Machine Brief Details

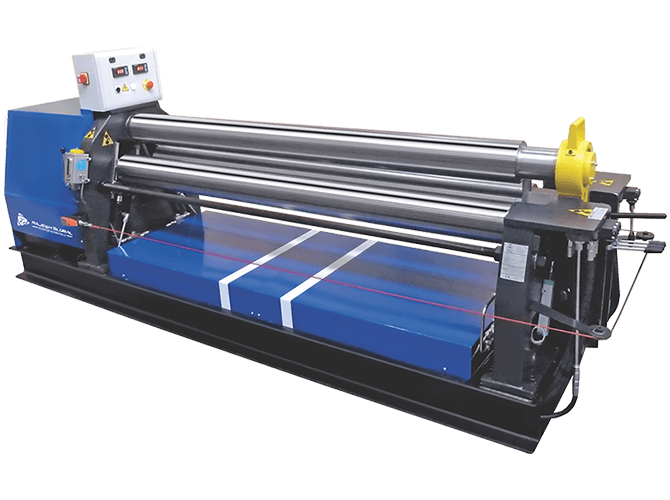

What is a Plate Rolling Machine? During the metalworking process known as “plate rolling,” workers deform a metal plate or sheet to create a curved or cylindrical shape. Various industries commonly use this method to manufacture pipes, tanks, pressure vessels, and other curved or cylindrical parts. Plate metal rolling is more exact than other processes, allowing for the creation of thinner, stronger metals with less industrial waste.

During the plate rolling process, workers roll metal sheets into cylindrical objects such as pipelines, buckets, and tanker trucks. The rolling machine’s mechanism allows it to bend flat sheet metal into complex shapes, including multisection arcs, huge cylinders, squares, and ellipses.

Single and double-pinch plates or sheet-bending rolls are available, however, they may differ in appearance or geometry. Three-roll double-pinch, four-roll double-pinch, three-roll variable translating, three-roll pyramid, and two-roll systems are common machine styles. For specific purposes, plate rolls are also made in a vertical shape. It’s crucial to match the best machine style to the application.

Type of Plate Rolling Machines

On the market, there are many different kinds of plate rolls. The symmetrical three-roll plate rolling machine, the arc downward adjustment three-roll plate rolling machine, the horizontal lower roll move three-roll plate rolls, and the vertical lower roll move three-roll plate rolls are a few of the most well-liked models.

Working Principle

External force flexibly deforms steel plate during rolling. The outer layer stretches, the inner layer shortens, and the intermediate layer remains unchanged. Fibre stretching and compression determine the deformation extent.

Read More: CNC Bending Machine Overview

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.