RG – Cut CNC

(Hydraulic Shearing Machine)

Advantages

Standard Equipments

Features

RG – Cut CNC Features

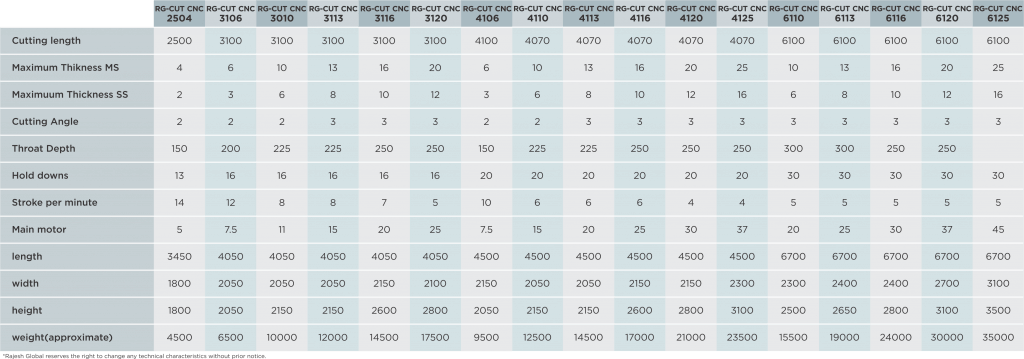

Adjustable Goniometer for Angle Cutting

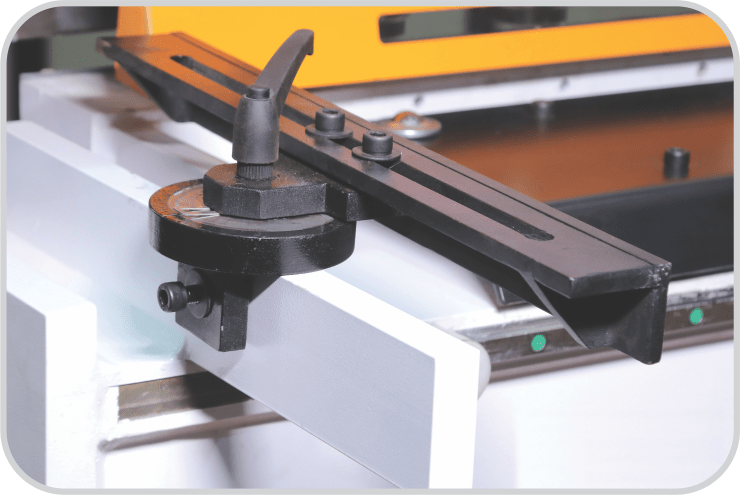

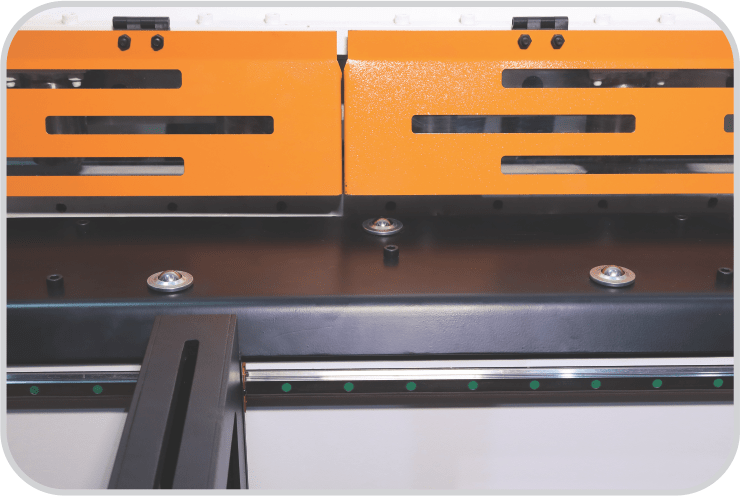

Movable Front Gauge with Linear Guide

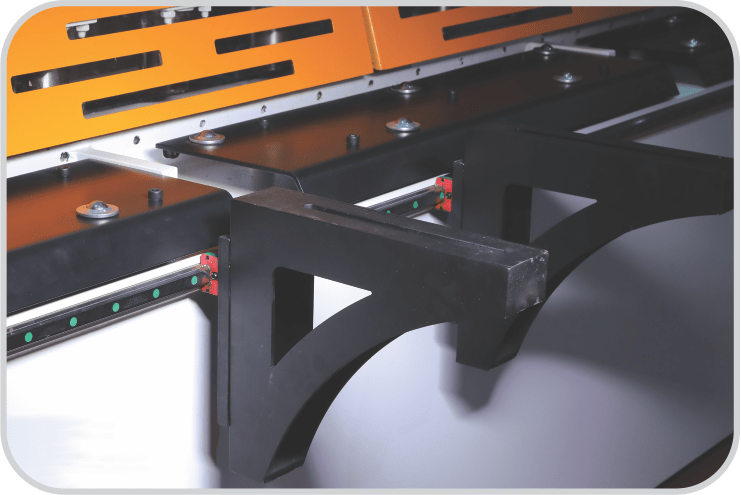

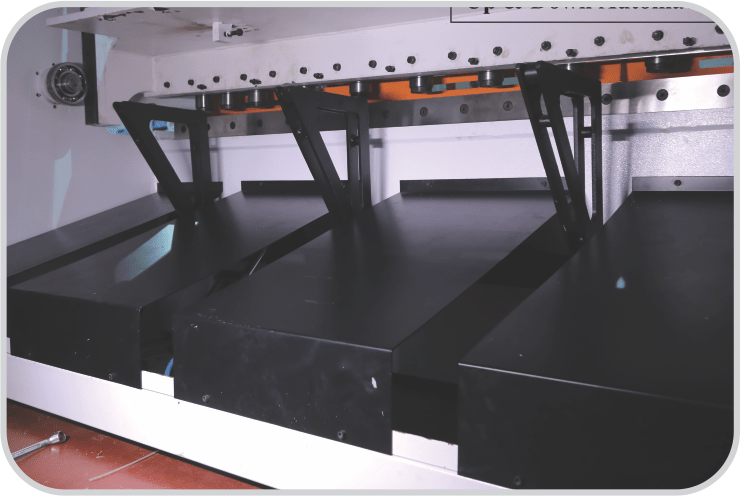

Rear Sheet Support

Rear Sheet Support Up and Down Automatic

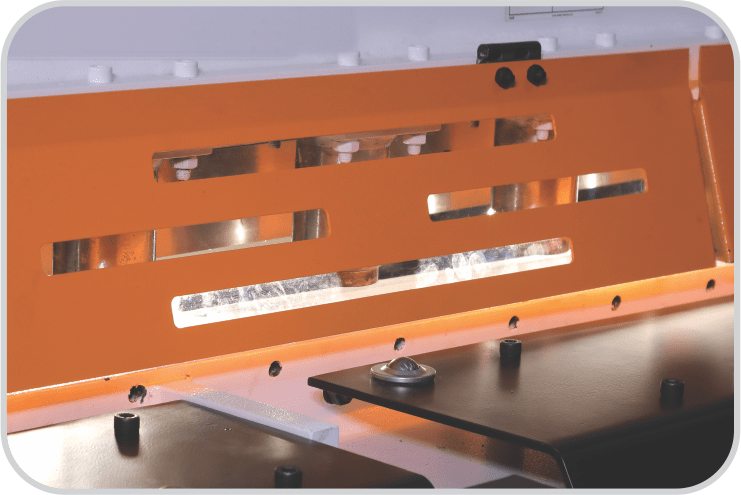

Front Safety Guard

Front Safety with Laser Light

Front Table Transfer Ball Type for Easy Way Moving of Sheet Shearing

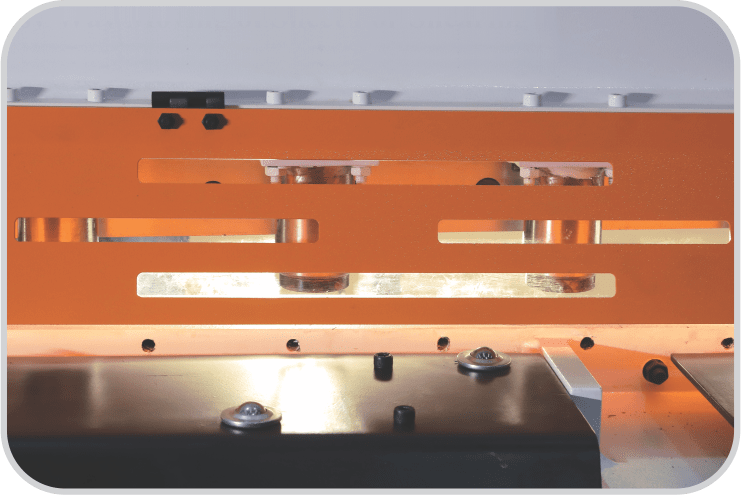

Automatic Sheet Thickness Features

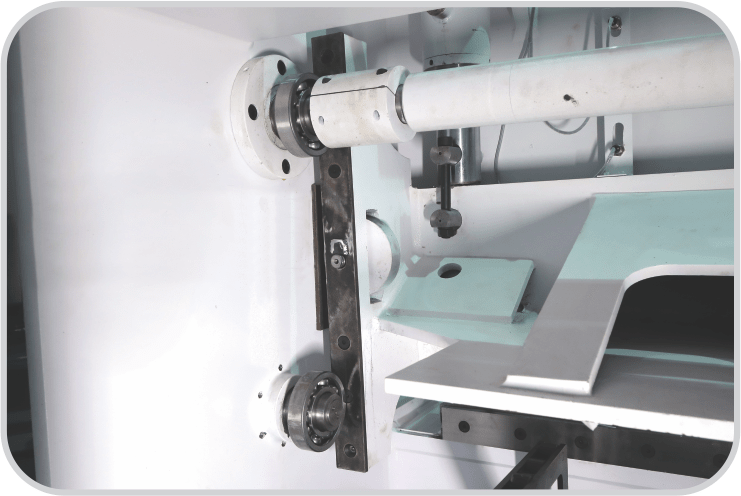

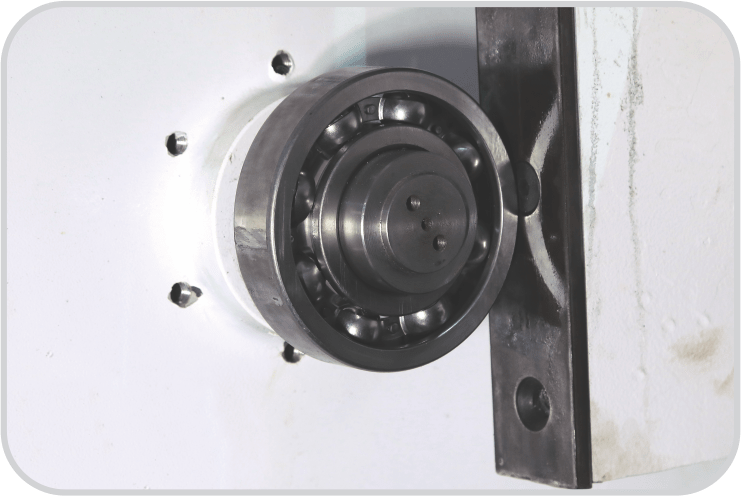

Beam Moving By Heavy Duty Bearing

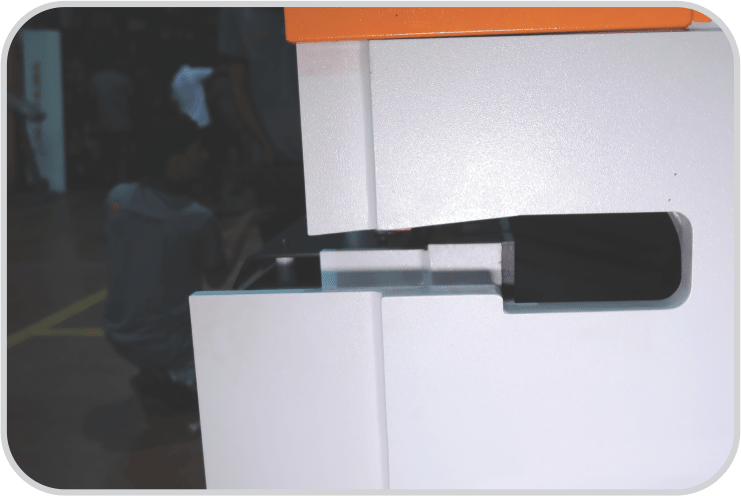

Throat Depth for Extra Sheet Length Cutting

FAQs

What is a Cut CNC Hydraulic Shearing Machine?

Hydraulic shearing machines assist in the cutting of sheets and metals that would otherwise be difficult to cut. These machines utilize two blades – an upper movable blade and a lower fixed blade – to shear metal plates of different thicknesses.

Use of Cut CNC hydraulic shearing machine?

Shearing machines are the most effective way to cut metals into various shapes and sizes. As a result, it is widely accepted in industries that use sheets and metals. Shearing machines are used by machinists to perform snipping, able to piece, roll-slitting, and blanking on metal sheets.

Shortening the CNC hydraulic shearing machine's length?

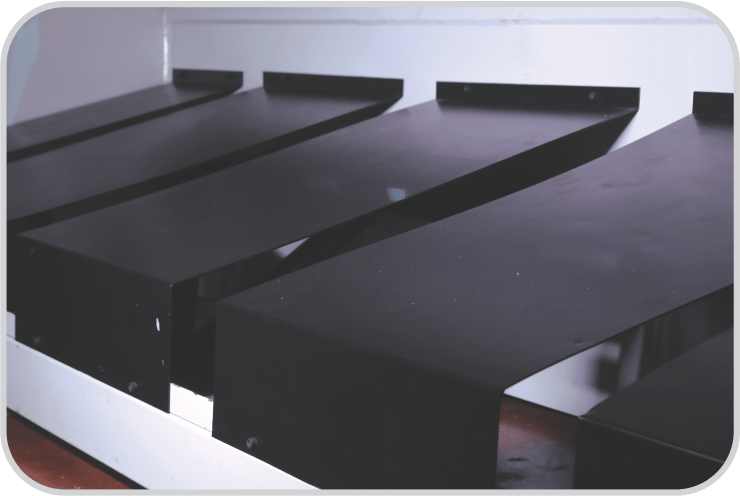

The cutting length of a CNC hydraulic shearing machine ranges from 2000 mm to 6000 mm.

What is the feature of the CNC hydraulic shearing machine?

Here we mentioned some features of this machine.

- Adjustable goniometer for angel cutting

- Movable front gauge with linear guide

- Rear sheet support

- Rear sheet support up & down automatic

- Front safety guard

- Front safety with laser light

- Automatic sheet thickness, etc.

What is the standard equipment of this machine?

Here we mentioned some standard feature equipment of this machine.

- Hydraulic shear with maximum variable rake angle Heavy duty rigid all welded steel frame, 7-inch color touch screen

- More grip near the squaring arm for improved holding and cutting of small parts

- Bal screw with automatic programming and high-speed AC servo motor back gauge

- Cutting blades designed specifically for mild steel and stainless steel

- Front safety guard Electrical components Schneider Electric/Siemens