Blog

Mechanical Press Machine

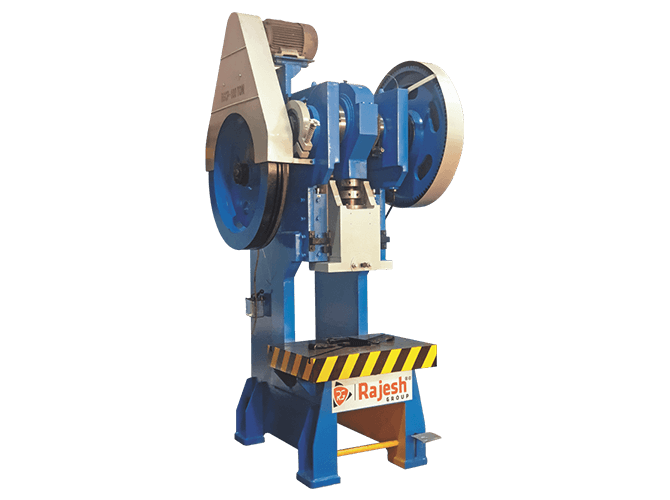

What is A Mechanical Press Machine?

A mechanical press machine cuts, punches, shapes or assembles metal or other materials using tools or dies attached to slides or frames. The metalworker places the material on the lower die and strikes it with the upper die to perform metalworking.

How Does it Work?

Mechanical pressing uses an electric motor that rotates the belt connected to the flywheel. It is driven by a series of gears. These gears move the ram up and down. The clutch and brake system connects the air wheel to enable its rotation without moving the ram during the press’s initial stage.

Difference Between a Mechanical Press and a Hydraulic Press

Although these two have the same goal, it is important that we understand their important differences. A mechanical press usually has a higher production speed, while a hydraulic press offers more flexibility for more complex forming processes.

Mechanical press machines play a vital role in modern manufacturing, enabling efficient shaping and forming of materials across various industries. With their robust construction, versatility, and ability to deliver high force, these machines contribute to improved productivity, consistent quality, and cost-effective production processes. Embracing mechanical press technology can lead to enhanced manufacturing capabilities and a competitive edge in the market.

Read more: What is a Press Brake Machine?

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.