Blog

Mechanical Power Press Machines for Automotive Component Manufacturing

The automotive industry is one of the most demanding manufacturing sectors in the world. Precision, speed, consistency, and durability are non-negotiable when producing automotive components. From body panels and chassis parts to brackets, frames, and structural elements, manufacturers rely heavily on advanced press machines to meet high production volumes without compromising quality.

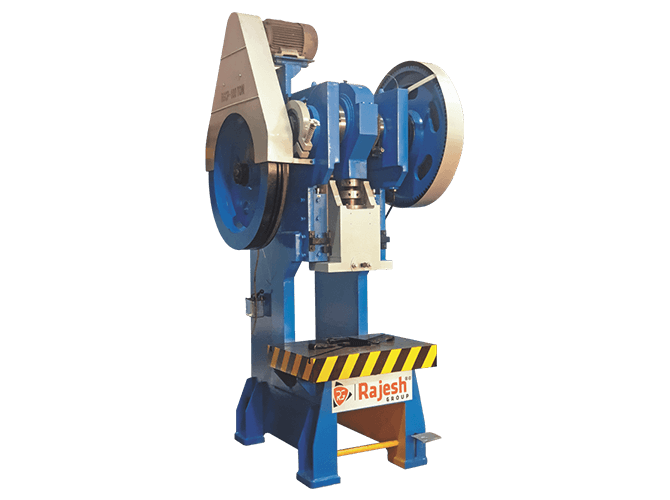

Among these, C Type Mechanical Power Press play a vital role in shaping, cutting, and forming metal components with unmatched efficiency. This blog explores how mechanical power press machines support automotive component manufacturing, their advantages, applications, and how related machinery contributes to a complete, high-performance production ecosystem.

Introduction to Mechanical Power Press Machines

Contents

- 1 Introduction to Mechanical Power Press Machines

- 2 Why Mechanical Power Press Machines Are Essential for Automotive Manufacturing

- 3 Common Automotive Applications of Mechanical Power Press Machines

- 4 Understanding C-Type Mechanical Power Press Machines

- 5 Mechanical Presses vs Hydraulic Systems in Automotive Production

- 6 Role of Hydraulic Iron Worker in Automotive Fabrication

- 7 Importance of Plate Rolling in Automotive Component Manufacturing

- 8 CNC Press Brake Machines for Precision Automotive Parts

- 9 Hydraulic Press Brake Machines for Heavy-Duty Applications

- 10 Front Cylinder Press Brake Machines: Enhanced Stability and Accuracy

- 11 CNC Hydraulic Shearing Machines in Automotive Production

- 12 Integrated Manufacturing Workflow in Automotive Plants

- 13 Advantages of Mechanical Power Press Machines for Automotive Industry

- 14 Future Trends in Automotive Press Manufacturing

Mechanical power press machines operate using a mechanical flywheel system that stores energy and releases it through a crankshaft, eccentric, or knuckle mechanism. This motion delivers powerful force to shape, punch, or form metal sheets with high repeatability.

In automotive manufacturing, where thousands of identical components are produced daily, mechanical presses provide the speed and consistency required to maintain production flow while ensuring accurate tolerances.

Unlike manual or low-capacity machines, mechanical presses are specifically designed for heavy-duty industrial workloads, making them an ideal choice for automotive OEMs and Tier-1 suppliers.

Why Mechanical Power Press Machines Are Essential for Automotive Manufacturing

Automotive component manufacturing demands machines that can perform repetitive tasks at high speed without wear-related inaccuracies. Mechanical power presses excel in:

- High stroke rates for mass production

- Reliable dimensional accuracy

- Low cycle time

- Consistent force application

- Cost-effective long-term operation

These characteristics allow manufacturers to produce body parts, reinforcement components, brackets, bushings, and structural elements efficiently.

Common Automotive Applications of Mechanical Power Press Machines

Mechanical power press machines are used across multiple stages of automotive production, including:

- Blanking and punching of sheet metal

- Deep drawing of panels

- Progressive die operations

- Coining and embossing

- Bending and forming operations

Components such as door panels, hood parts, seat structures, engine mounts, and chassis brackets are commonly manufactured using mechanical presses.

Understanding C-Type Mechanical Power Press Machines

The C Type Mechanical Power Press is particularly popular in automotive workshops due to its open-frame design. This structure allows easy access to the die area from three sides, making it highly suitable for operations that require frequent tool changes or manual feeding.

Key Advantages:

- Compact and space-saving design

- Easy die installation and maintenance

- High productivity for medium-size components

- Excellent visibility for operators

In automotive production, C-type presses are ideal for producing brackets, clamps, small panels, and reinforcement parts where speed and accessibility are critical.

Mechanical Presses vs Hydraulic Systems in Automotive Production

While mechanical presses dominate high-speed production, they often work alongside hydraulic systems to complete the manufacturing process.

For example, a C Frame Hydraulic Pressis often used when variable pressure, longer dwell time, or deep forming is required. Hydraulic presses are widely used for operations such as deep drawing, straightening, and precision forming of thicker materials.

Combining mechanical and hydraulic presses enables automotive manufacturers to achieve both speed and flexibility within the same facility.

Role of Hydraulic Iron Worker in Automotive Fabrication

The Hydraulic Iron Worker is another essential machine in automotive component manufacturing. While not a press in the traditional sense, it performs multiple metal processing functions, including punching, shearing, notching, and bending.

Applications in Automotive Industry:

- Cutting flat bars and angles

- Punching mounting holes

- Notching sheet metal parts

- Preparing structural components

Iron workers help reduce setup time and improve workshop efficiency, especially during fabrication of frames, brackets, and support structures.

Importance of Plate Rolling in Automotive Component Manufacturing

Plate – Rolling machines are used to bend flat metal sheets into cylindrical or conical shapes. In the automotive sector, plate rolling is critical for manufacturing:

- Fuel tanks

- Exhaust components

- Structural tubes

- Curved reinforcement panels

By integrating plate rolling machines with mechanical presses, manufacturers can handle both flat and curved component production under one roof, improving workflow and reducing outsourcing costs.

CNC Press Brake Machines for Precision Automotive Parts

Automotive components often require precise bending angles and consistent repeatability. This is where the CNC Press Brake Machine becomes indispensable.

CNC press brakes use computerized controls to ensure exact bend angles, back-gauge positioning, and consistent results across large batches.

Benefits:

- High bending accuracy

- Reduced material wastage

- Faster setup time

- Easy programming for complex parts

Components such as brackets, frames, and support structures are manufactured efficiently using CNC press brake technology.

Hydraulic Press Brake Machines for Heavy-Duty Applications

The Hydraulic Press Brake Machine is preferred when working with thicker materials or larger components that require controlled bending force.

In automotive plants, hydraulic press brakes are used for:

- Chassis components

- Frame rails

- Structural reinforcements

- Heavy-duty brackets

Unlike mechanical presses, hydraulic press brakes offer adjustable pressure and stroke length, making them suitable for varied component designs.

Front Cylinder Press Brake Machines: Enhanced Stability and Accuracy

The Front Cylinder Press Brake Machine features hydraulic cylinders positioned at the front of the machine, offering improved control, better synchronization, and higher bending accuracy.

Why Automotive Manufacturers Prefer It:

- Enhanced visibility of bending area

- Uniform pressure distribution

- Suitable for large and complex components

- Improved operator safety

This type of press brake is particularly useful for long automotive panels and precision structural parts.

CNC Hydraulic Shearing Machines in Automotive Production

Sheet metal preparation is a crucial step before pressing and forming. The CNC Hydraulic Shearing Machine ensures clean, accurate, and burr-free cutting of metal sheets before they enter press operations.

Key Benefits:

- High cutting accuracy

- Smooth edge finish

- Programmable cutting lengths

- Faster production cycles

Automotive manufacturers rely on CNC hydraulic shearing machines to maintain consistency and reduce downstream processing issues.

Integrated Manufacturing Workflow in Automotive Plants

Modern automotive plants operate on highly integrated production systems. Mechanical power presses work in coordination with:

- Hydraulic Iron Worker for fabrication

- Plate – Rolling machines for curved parts

- CNC Press Brake Machine for precision bending

- Hydraulic Press Brake Machine for heavy components

- Front Cylinder Press Brake Machine for accuracy

- CNC Hydraulic Shearing Machine for sheet preparation

This integration helps manufacturers reduce lead times, optimize resource usage, and maintain strict quality standards.

Advantages of Mechanical Power Press Machines for Automotive Industry

Mechanical power presses offer several advantages that make them indispensable for automotive component manufacturing:

- High production speed for mass manufacturing

- Consistent performance across long shifts

- Lower operational cost compared to repetitive hydraulic operations

- Durable construction for continuous industrial use

- Compatibility with automation and robotic feeding systems

These benefits help automotive manufacturers meet tight delivery schedules without sacrificing quality.

Future Trends in Automotive Press Manufacturing

As electric vehicles and lightweight materials gain popularity, press machine technology is also evolving. Mechanical presses are now being integrated with smart sensors, automation systems, and predictive maintenance tools.

Key trends include:

- Servo-mechanical press technology

- Energy-efficient flywheel systems

- IoT-enabled production monitoring

- Automated tool change systems

These innovations ensure that mechanical power press machines remain relevant in next-generation automotive manufacturing.

Conclusion

Mechanical power press machines form the backbone of automotive component manufacturing. Their ability to deliver high-speed, precise, and repeatable performance makes them essential in producing reliable automotive parts at scale.

When combined with advanced machinery such as C Type Mechanical Power Press, Hydraulic Iron Worker, Plate – Rolling machines, C Frame Hydraulic Press, CNC Press Brake Machine, Hydraulic Press Brake Machine, Front Cylinder Press Brake Machine, and CNC Hydraulic Shearing Machine, manufacturers can build a comprehensive, efficient, and future-ready production setup.

By investing in the right combination of press technologies, automotive manufacturers can stay competitive, reduce costs, and deliver superior-quality components that meet global standards.