RG-Bend

(CNC Press Brake Machine)

Advantages of CNC Press Brake Machine

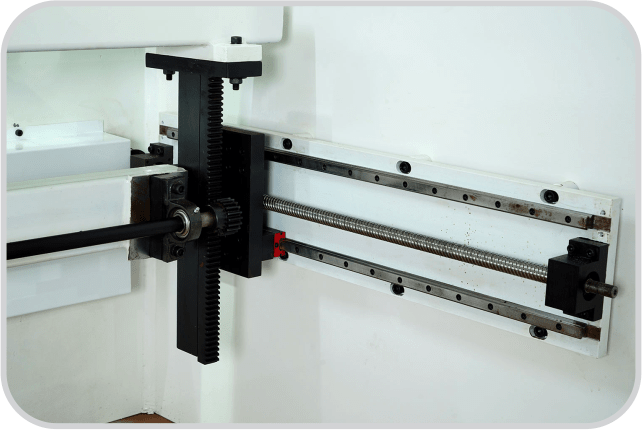

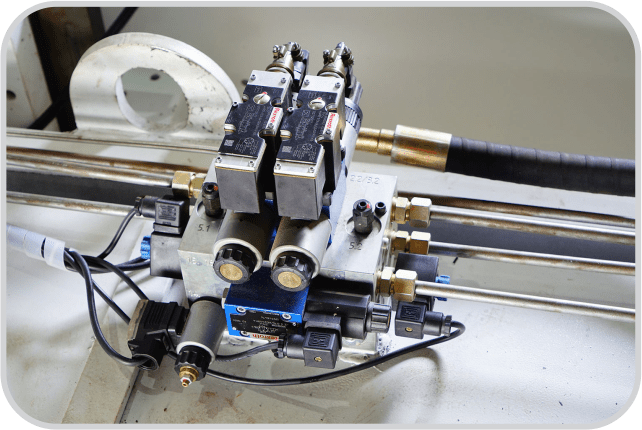

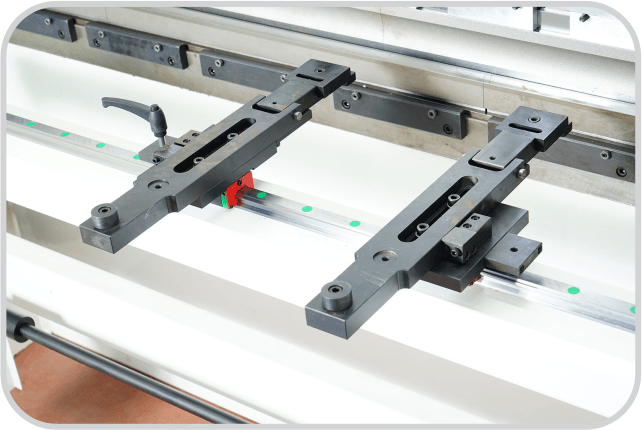

Standard Equipments

FAQs

Benefits of Bend CNC press brake machine?

It is the best-in-class world leader due to its simple-to-use control unit, rigid body frame, flawless design, high efficiency, multiple tool usage solutions, top CE safety standards, and reasonable price. It’s perfect for bend-sensitive, energy-saving solutions.

What is a CNC press brake machine?

A press brake is a piece of manufacturing machinery that bends sheet metal. A press brake can bend the metal several times until it reaches the desired shape.

Why do we use a CNC press brake machine?

Press brakes can make a wide range of bends on a large variety of metals. When designing a bending process, take into account the metal being bent, the die, the punch, and the bending force.

Advantage of CNC press brake machine?

Here we mentioned the advantages of CNC press brake machine.

- more adaptable

- fewer material wastes

- low-cost “S” and “U” production finalization

- Designing prototypes

What is the length-bending capacity?

Three different lengths—2600, 3100, and 4100 mm—can be able to bend.