Blog

C Type Mechanical Power Press Machine Working and Applications

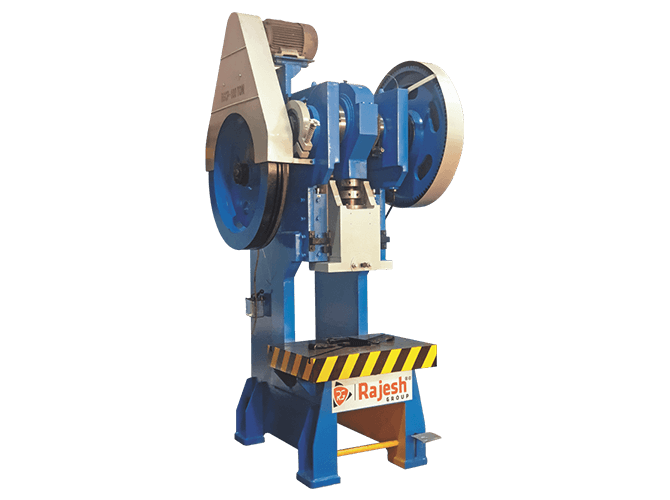

In today’s fast-growing metalworking and fabrication industries, choosing the right sheet-metal processing machine plays a major role in enhancing productivity, precision, and cost efficiency. Among the various forming machines used worldwide, the C Type Mechanical Power Press is one of the most versatile and reliable options for punching, bending, blanking, embossing, and deep drawing tasks. Its unique frame design, mechanical accuracy, and fast stroke speed make it indispensable for small, medium, and large-scale manufacturing units.

This blog explains in detail how a C Type Mechanical Power Press works, its technical advantages, major applications, and how it integrates with modern equipment such as the C Frame Hydraulic Press, CNC Press Brake Machine, Hydraulic Press Brake Machine, Front Cylinder Press Brake Machine, CNC Hydraulic Shearing Machine, Hydraulic Iron Worker, and Plate – Rolling machines.

The goal is to help manufacturers and buyers understand how this machine contributes to a productive, high-quality metal fabrication ecosystem.

1. Introduction to C Type Mechanical Power Press Machine

Contents

- 1 1. Introduction to C Type Mechanical Power Press Machine

- 2 2. Working Principle of C Type Mechanical Power Press

- 3 3. Features and Benefits of C Type Mechanical Power Press

- 4 4. Applications of C Type Mechanical Power Press Machine

- 5 5. Why C Type Mechanical Power Press Is Still in Demand Today

- 6 6. Integration with Other Metal-Forming Machines

- 7 7. Safety and Operator-Friendly Features

The C Type Mechanical Power Press gets its name from its frame shape, which resembles the letter “C.” This open-front frame design provides easy accessibility for loading and unloading workpieces, making the machine extremely user-friendly and efficient for repetitive tasks.

It is widely used in industries such as automotive, electrical components, hardware manufacturing, home appliances, agriculture equipment, and metal furniture production. The mechanical operation ensures superior accuracy, consistency in output, and high-speed operations compared to hydraulic systems.

The machine is designed for:

- Punching and blanking of sheets

- Forming and bending metal components

- Deep drawing operations

- Coining and embossing

- Cutting and pre-forming tasks

- Pressing and compacting operations

Because of its wide applicability, the C Type Mechanical Power Press remains a backbone machine for any metal fabrication unit.

2. Working Principle of C Type Mechanical Power Press

Understanding the working principle is essential for selecting the right press for your application.

Crank and Flywheel Mechanism

A core feature of the press is its crankshaft mechanism, powered by a flywheel. The flywheel stores energy from the electric motor and releases it during pressing operations, ensuring uniform force and stable performance.

Power Transmission

The flywheel is connected to the crankshaft, which converts rotational motion into linear motion. This linear motion drives the ram (slide) up and down for punching or forming metal sheets.

Stroke Adjustment

Operators can easily adjust the stroke length depending on the thickness of the sheet or depth of the operation. This flexibility makes the machine suitable for multiple types of jobs.

Mechanical Accuracy

Mechanical presses are known for their repeatability. Once the stroke and force are set, the output remains consistent, making them ideal for mass production.

3. Features and Benefits of C Type Mechanical Power Press

High Strength C Frame Design

The open “C” design allows operators to work comfortably, handle sheets easily, and achieve higher productivity.

High Precision Output

The machine ensures accurate punching, bending, and forming results.

It is commonly used alongside high-precision machines such as the CNC Press Brake Machine and Hydraulic Press Brake Machine.

Fast Production Rate

Mechanical presses operate faster than hydraulic presses, making them ideal for mass-production environments.

Low Maintenance & High Durability

Solid steel construction, reliable mechanical parts, and fewer hydraulic components reduce long-term maintenance costs.

Versatility in Applications

From small components to large sheet-metal parts, the machine supports various industries.

4. Applications of C Type Mechanical Power Press Machine

The C Type Mechanical Power Press is used in a wide range of industrial applications. Here are the top areas where this machine plays a crucial role:

Automotive Components Manufacturing

The automotive sector requires thousands of metal parts—small, medium, and large.

The press is used for:

- Body parts

- Brackets

- Transmission components

- Engine parts

- Dashboard frames

Pairing this machine with a C Frame Hydraulic Press helps in processes involving deep drawing and forming of stronger, thicker automotive components.

Electrical & Electronics Industry

This sector relies heavily on precise and lightweight sheet-metal components.

Applications include:

- Switchgear parts

- Electrical housings

- Control panel components

- Terminal connectors

Hardware & Tools Manufacturing

The press is widely used for manufacturing:

- Hand tool components

- Hinges

- Clamps

- Handles

- Metal brackets

Mechanical presses produce these parts with high precision and at high speed.

Home Appliance Industry

Manufacturers of refrigerators, washing machines, microwaves, coolers, and fans depend on mechanical presses for cutting, forming, and shaping sheet-metal parts.

Agriculture Equipment Manufacturing

Farming equipment requires durable and accurate components.

The press is used to form blades, clamps, support frames, and brackets.

Sheet-Metal Forming & Fabrication Units

Most fabrication workshops use mechanical presses along with advanced machines such as:

- CNC Hydraulic Shearing Machine for cutting

- CNC Press Brake Machine for bending

- Front Cylinder Press Brake Machine for heavy-duty operations

- Plate – Rolling machines for cylindrical shapes

- Hydraulic Iron Worker for punching, notching, and angle cutting

Together, these machines create a complete production line capable of handling all metal-forming needs.

5. Why C Type Mechanical Power Press Is Still in Demand Today

Even with the rise of automation and CNC systems, the C Type Mechanical Power Press remains relevant because:

Low Operating Cost

Mechanical systems use less power and require fewer maintenance procedures.

High Production Speed

For mass production, mechanical presses outperform hydraulic machines.

Compatibility with Modern CNC Machines

This creates a hybrid production environment that offers both speed and precision.

Ideal for Small to Large-Scale Industries

Whether you produce small hardware parts or large metal components, the C Type press can handle diverse operations.

6. Integration with Other Metal-Forming Machines

A modern workshop does not rely on a single machine. Instead, multiple machines work together to complete various tasks effectively.

Here is how the C Type Mechanical Power Press integrates with your other mentioned machines:

With Hydraulic Iron Worker

The Hydraulic Iron Worker handles notching, punching, angle cutting, and flat bar cutting—ideal for pre-processing before pressing.

With Plate – Rolling Machines

After cutting and punching, Plate – Rolling machines shape sheets into pipes, cylinders, and cones.

With C Frame Hydraulic Press

This press is perfect for deep drawing tasks that require higher tonnage and continuous hydraulic pressure.

With CNC Hydraulic Shearing Machine

Provides accurate sheet cutting before feeding material into the mechanical press.

With CNC Press Brake Machine

Used for bending complex shapes after punching operations.

With Hydraulic Press Brake Machine

Supports larger, heavy-duty bending tasks that require uniform hydraulic pressure.

With Front Cylinder Press Brake Machine

Ensures precision bending with superior force distribution from front-mounted cylinders.

7. Safety and Operator-Friendly Features

Modern mechanical presses come with safety features such as:

- Dual-hand operation

- Mechanical overload protection

- Emergency stop systems

- Guarding around critical moving parts

- Adjustable stroke controls

These features make the press highly reliable and safe for continuous use.

Conclusion

The C Type Mechanical Power Press continues to be a preferred machine for sheet-metal fabrication due to its high speed, precision, durability, and versatility. Whether you are manufacturing automotive components, electrical parts, furniture, or hardware items, this machine can significantly boost your productivity.

Moreover, when integrated with other advanced equipment like the Hydraulic Iron Worker, C Frame Hydraulic Press, CNC Press Brake Machine, CNC Hydraulic Shearing Machine, Hydraulic Press Brake Machine, Front Cylinder Press Brake Machine, and Plate – Rolling machines, it becomes part of a powerful, efficient, and modern fabrication ecosystem.

If your goal is to improve production quality, reduce operational cost, and achieve faster output, investing in a C Type Mechanical Power Press is an excellent choice for long-term success.