Blog

Hydraulic Press Brake Machine in Gujarat

Experience precision and efficiency with Hydraulic Press Brake Machines from Rajesh Machine Tools Pvt. Ltd. in Gujarat. Our machines feature a robust steel frame, compact cylinder design, and versatile operation modes, ensuring high-quality metal bending for various industries. Enhance your production capabilities with our advanced and reliable equipment.

Precision Engineering with Hydraulic Press Brake Machine in Gujarat

Contents

- 1 Precision Engineering with Hydraulic Press Brake Machine in Gujarat

- 2 Technical Specification

- 3 Key Features of Our Hydraulic Press Brake Machines

- 4 Benefits of Hydraulic Press Brake Machines

- 5 Applications of Hydraulic Press Brake Machines

- 6 Why Invest in Hydraulic Press Brake Machines?

- 7 Maintenance Tips for Hydraulic Press Brake Machines

- 8 Conclusion

Rajesh Machine Tools Pvt. Ltd., located in Gujarat, is a leading manufacturer of Hydraulic Press Brake Machines. These machines, essential for various industries, offer precision, durability, and efficiency.

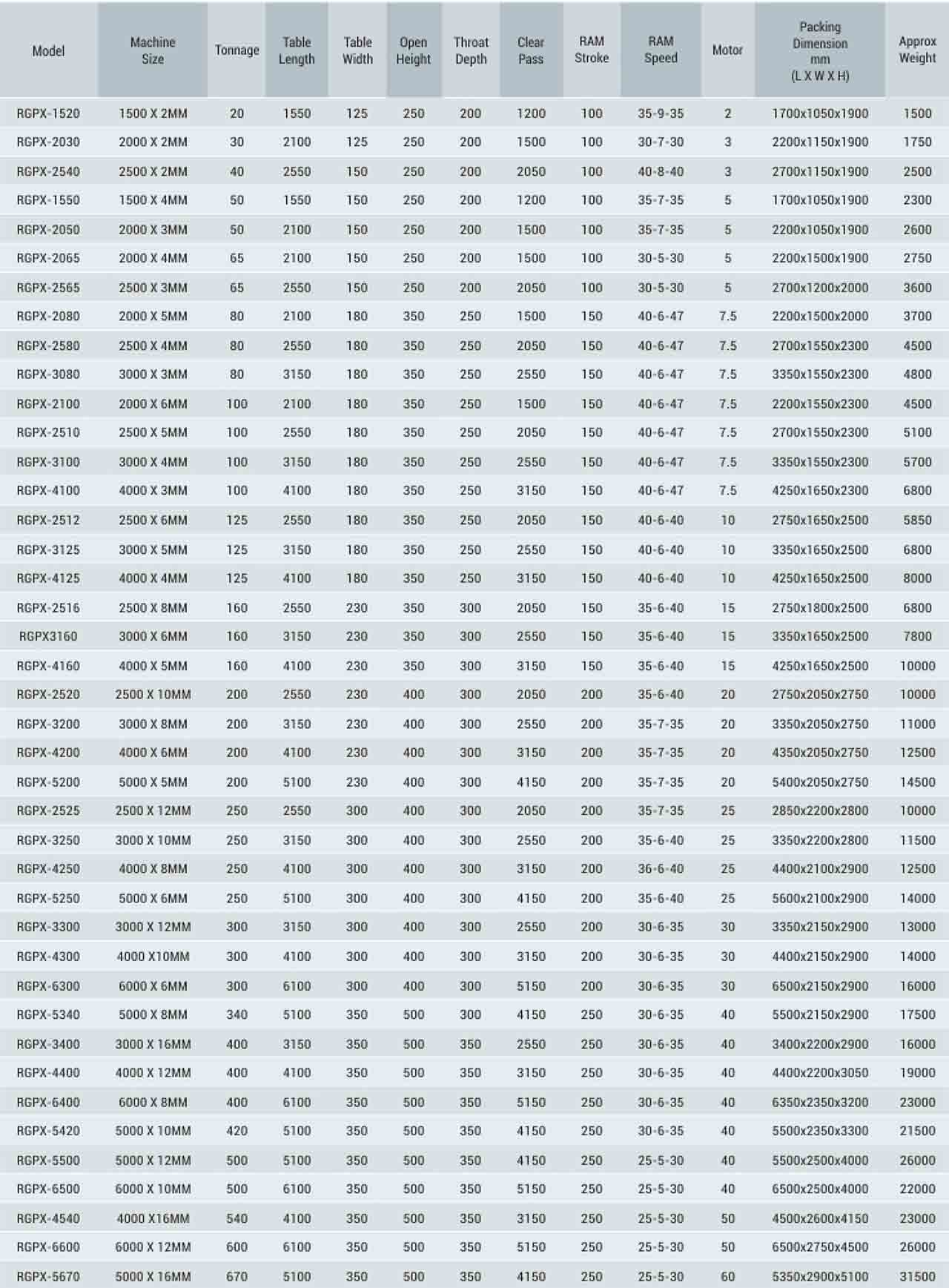

Technical Specification

Key Features of Our Hydraulic Press Brake Machines

- Robust Welded Steel Frame Structure: The machines boast a strong, welded steel frame structure, providing stability and longevity.

- Compact Cylinder Design: The compact cylinder design, coupled with the rear cylinder system, requires low pressure, enhancing efficiency.

- Electrical Control Panel: The electrical control panel allows for multiple mode selections, including inch, single cycle, and auto mode operation.

- Mobile Foot Switch Panel: A mobile pair of foot switch panels provides ease of operation and flexibility.

- Front Sheet Support: The front sheet support, measuring 600 mm in length, ensures accurate sheet handling and positioning.

- Fine Stroke Adjustment: For fine stroke adjustments, an adjustment rod with a limit switch is provided, ensuring precision.

- Manual Back Gauge: The front-operated manual back gauge, fitted with a lead screw, allows for precise adjustments.

- Standard Die and Punch: The standard 5 “V” die made of EN-8 material and the punch made of EN-31 (both unhardened) offer robust performance.

- Centralized Lubrication System: The centralized lubrication system ensures smooth and efficient operation.

- Ram Tilting Arrangement: The ram tilting arrangement on the outer right side of the machine provides additional operational flexibility.

Benefits of Hydraulic Press Brake Machines

- Enhanced Precision: Hydraulic Press Brake Machines deliver high precision in metal bending, ensuring consistent results.

- Increased Efficiency: The compact cylinder design and rear cylinder system reduce pressure requirements, enhancing operational efficiency.

- Versatile Operation: With multiple mode selections and a mobile foot switch panel, these machines offer versatile and flexible operation.

- Durability and Stability: The robust welded steel frame structure ensures the machine’s durability and stability, even under heavy-duty operations.

Applications of Hydraulic Press Brake Machines

Hydraulic Press Brake Machines are widely used in various industries for bending and shaping metal sheets. Their applications include:

- Automotive Industry: Essential for manufacturing automotive components with precise bends and angles.

- Construction Industry: Used in the fabrication of structural elements, ensuring accuracy and strength.

- Aerospace Industry: Critical for producing high-precision parts for aircraft and spacecraft.

- Metal Fabrication: Ideal for general metal fabrication tasks, providing consistent and accurate results.

- Heavy Machinery: Used in the production of components for heavy machinery, ensuring robustness and precision.

Why Invest in Hydraulic Press Brake Machines?

Investing in Hydraulic Press Brake Machines offers numerous benefits:

- Cost-Effective: These machines reduce material waste and increase production efficiency, offering cost savings.

- High Precision: They provide high precision in metal bending, essential for producing high-quality components.

- Versatility: Suitable for a wide range of applications, making them a versatile addition to any manufacturing setup.

- Durability: Built to last, these machines offer long-term reliability and performance.

Maintenance Tips for Hydraulic Press Brake Machines

To ensure the longevity and optimal performance of your Hydraulic Press Brake Machine, follow these maintenance tips:

- Regular Lubrication: Ensure the centralized lubrication system is regularly checked and maintained.

- Routine Inspections: Conduct routine inspections to identify and address any potential issues promptly.

- Cleanliness: Keep the machine clean and free from debris to prevent operational issues.

- Proper Storage: Store the machine in a dry and secure environment to protect it from environmental damage.

- Operator Training: Ensure operators are well-trained in using and maintaining the machine to prevent mishandling.

Conclusion

Hydraulic Press Brake Machines by Rajesh Machine Tools Pvt. Ltd. are a valuable addition to any industry requiring precise metal bending and shaping. With their robust construction, versatile operation, and high efficiency, these machines offer unparalleled performance and reliability. Investing in these machines not only enhances production capabilities but also ensures long-term cost savings and operational efficiency.

Ready to enhance your manufacturing capabilities with our Hydraulic Press Brake Machines? Contact Us to learn more and make an inquiry.

Read About: Mechanical Power Press Machine in Gujarat

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.