Blog

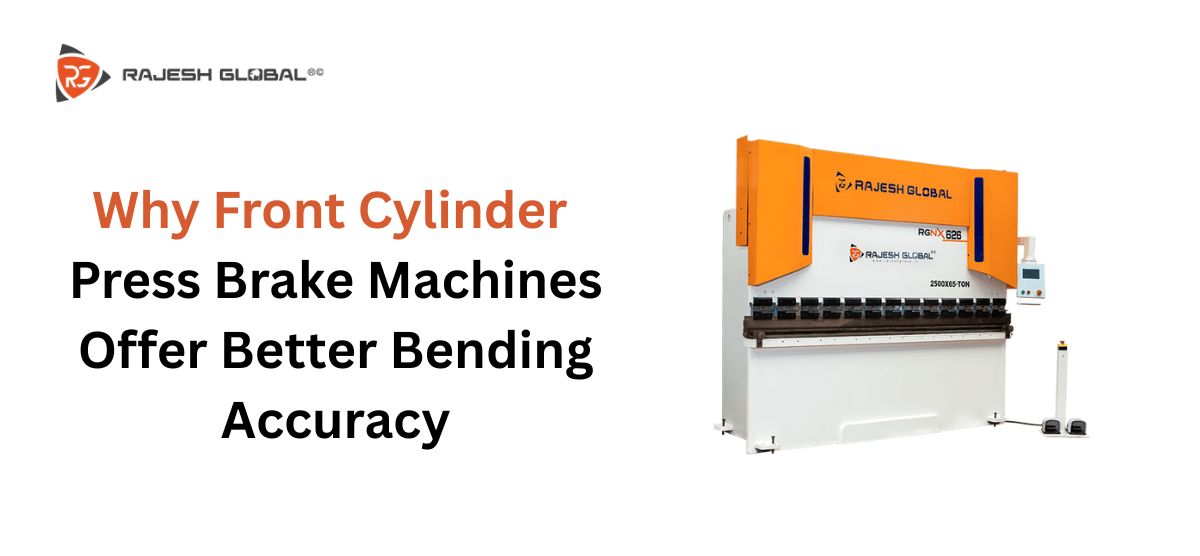

Why Front Cylinder Press Brake Machines Offer Better Bending Accuracy

In today’s competitive manufacturing environment, precision, consistency, and efficiency are no longer optional—they are essential. Metal fabrication industries, from heavy engineering to fine sheet metal work, rely heavily on press brake machines to achieve accurate bends and flawless finishes. Among the many types available in the market, the Front Cylinder Press Brake Machine has emerged as a preferred choice for manufacturers who demand superior bending accuracy and long-term reliability.

This blog explores why front cylinder press brake machines outperform conventional designs in bending accuracy. We will also compare them with other metal fabrication machines such as the Hydraulic Press Brake Machine, CNC Press Brake Machine, C Type Mechanical Power Press, and more—helping you understand where each machine fits within a modern fabrication setup.

Understanding the Basics of Press Brake Machines

Contents

- 1 Understanding the Basics of Press Brake Machines

- 2 What Is a Front Cylinder Press Brake Machine?

- 3 Key Reasons Front Cylinder Press Brake Machines Deliver Better Accuracy

- 4 Comparison with Other Metal Fabrication Machines

- 5 Operational Benefits Beyond Accuracy

- 6 Industries That Benefit Most from Front Cylinder Press Brake Machines

- 7 Why Manufacturers Are Shifting Toward Front Cylinder Technology

A press brake machine is used to bend sheet metal into various shapes and angles using a punch and die system. Accuracy in bending depends on several factors:

- Even distribution of bending force

- Stable machine frame

- Precise ram movement

- Consistent hydraulic or mechanical control

Traditional press brake machines often face challenges such as uneven load distribution and frame deflection, especially when working with long or thick sheets. This is where front cylinder technology offers a noticeable advantage.

What Is a Front Cylinder Press Brake Machine?

A Front Cylinder Press Brake Machine is designed with hydraulic cylinders positioned at the front of the machine frame instead of the conventional side-mounted or rear-mounted cylinder setup. This structural change may appear minor, but it significantly improves bending performance.

By placing the cylinders closer to the bending line, the machine minimizes torsional stress and frame distortion, resulting in better control over the bending process.

Key Reasons Front Cylinder Press Brake Machines Deliver Better Accuracy

1. Improved Force Distribution Across the Bending Length

One of the biggest challenges in press brake operations is maintaining uniform force across the entire bending length. In conventional machines, uneven pressure can cause angle variations, especially on longer sheets.

Front cylinder designs apply force closer to the bending area, ensuring even pressure distribution. This results in:

- Consistent bend angles

- Reduced need for rework

- Better repeatability across production batches

This is a major reason manufacturers seeking tight tolerances prefer front cylinder machines over standard Hydraulic Press Brake Machine models.

2. Reduced Frame Deflection

Frame deflection directly affects bending accuracy. Even a small amount of frame movement can lead to inaccurate bends, especially in high-tonnage applications.

Front cylinder machines reduce the bending moment acting on the frame by positioning the cylinders near the center of force application. This minimizes deflection and ensures the punch follows a precise vertical path.

Compared to older mechanical systems like the C Type Mechanical Power Press, which are more prone to deflection under load, front cylinder press brakes offer significantly better structural stability.

3. Superior Ram Parallelism

Ram parallelism is crucial for achieving uniform bends from one end of the sheet to the other. Any misalignment results in uneven angles and poor edge quality.

Front cylinder configurations naturally support better ram alignment due to symmetrical force application. When combined with CNC controls, this leads to exceptional accuracy.

This is why front cylinder designs are often integrated into advanced CNC Press Brake Machine systems for industries that demand micron-level precision.

4. Enhanced Compatibility with CNC Control Systems

Modern fabrication units increasingly rely on automation and digital control. Front cylinder press brake machines integrate seamlessly with CNC systems, allowing operators to:

- Program precise bend angles

- Store bending sequences

- Automatically compensate for material thickness variations

When paired with a CNC Press Brake Machine, front cylinder technology ensures that each programmed bend is executed accurately and repeatedly, reducing operator dependency and human error.

5. Better Performance with High-Strength Materials

As industries shift toward high-strength steels and advanced alloys, bending accuracy becomes harder to maintain. These materials require higher tonnage and more control during the bending process.

Front cylinder machines handle these challenges efficiently by:

- Delivering stable pressure at the bending point

- Reducing vibration during operation

- Maintaining consistent angles even under high loads

This makes them a strong companion machine alongside equipment like Plate – Rolling machines and Hydraulic Iron Worker units in heavy fabrication workshops.

Comparison with Other Metal Fabrication Machines

To understand the value of front cylinder press brakes, it helps to see how they fit within a complete fabrication setup.

Hydraulic Press Brake Machine vs. Front Cylinder Design

A standard Hydraulic Press Brake Machineuses side-mounted or rear-mounted cylinders. While effective, these machines may experience uneven force distribution on long sheets.

Front cylinder models enhance the hydraulic principle by optimizing cylinder placement, offering better bending accuracy without compromising hydraulic power.

CNC Press Brake Machine Integration

When front cylinder architecture is combined with CNC automation, the result is exceptional precision. CNC systems handle calculations and motion control, while the front cylinder structure ensures mechanical accuracy.

This combination is ideal for high-volume, high-precision manufacturing environments.

C Frame Hydraulic Press and Mechanical Presses

A C Frame Hydraulic Press or C Type Mechanical Power Press is suitable for punching, forming, and stamping operations but lacks the controlled bending accuracy of a press brake.

While these machines play an important role in fabrication, they cannot replace the precision offered by a front cylinder press brake when it comes to angle consistency and long bends.

CNC Hydraulic Shearing Machine in the Workflow

Before bending, sheets often need precise cutting. A CNC Hydraulic Shearing Machine ensures accurate sheet dimensions, which directly impacts bending accuracy.

When used together, shearing machines and front cylinder press brakes form a highly efficient and precise fabrication line.

Operational Benefits Beyond Accuracy

1. Reduced Setup Time

Front cylinder press brake machines typically require fewer adjustments to achieve accurate results. Operators spend less time fine-tuning angles and more time producing quality components.

2. Lower Maintenance Requirements

Due to reduced frame stress and smoother ram movement, front cylinder machines experience less wear on critical components. This results in:

- Longer machine life

- Lower maintenance costs

- Improved uptime

3. Improved Operator Safety

Stable operation and predictable ram motion reduce the risk of sudden movements or misalignment. This creates a safer working environment, especially in high-tonnage applications.

Industries That Benefit Most from Front Cylinder Press Brake Machines

Front cylinder press brake machines are widely used in industries such as:

- Automotive components manufacturing

- Electrical panel fabrication

- Construction and infrastructure

- Heavy engineering and machinery

- Precision sheet metal workshops

In these sectors, even small bending errors can lead to costly rejections. High accuracy is not just an advantage—it’s a necessity.

Why Manufacturers Are Shifting Toward Front Cylinder Technology

Manufacturers today are under constant pressure to improve quality while reducing production costs. Front cylinder press brake machines support these goals by offering:

- Higher accuracy with less rework

- Better repeatability across batches

- Compatibility with automation and CNC systems

- Long-term operational stability

When combined with other essential machines such as Hydraulic Iron Worker, Plate – Rolling, and CNC Hydraulic Shearing Machine, they form the backbone of a modern, efficient fabrication facility.

Final Thoughts

Choosing the right press brake machine is a critical decision for any fabrication business. While many options exist, the Front Cylinder Press Brake Machine clearly stands out when bending accuracy, consistency, and reliability are top priorities.

Its superior force distribution, reduced frame deflection, excellent ram alignment, and seamless CNC integration make it an ideal solution for both medium-scale and large-scale production environments. Compared to traditional machines, front cylinder designs deliver measurable improvements in quality and efficiency—helping manufacturers stay competitive in a demanding market.

If your business focuses on precision, reduced waste, and high-quality output, investing in a front cylinder press brake machine is not just an upgrade—it’s a strategic advantage.