Blog

Why C-Type Press Machines Remain the Top Choice in Sheet Metal Industries

In the evolving world of metal fabrication, efficiency, precision, and long-term durability are essential. Among the wide range of machinery used for sheet metal processing, C-Type Press Machines stand out as one of the most preferred and trusted solutions. From small workshops to large-scale manufacturing plants, these machines deliver unmatched performance, operational convenience, and versatility.

Industries today rely on a combination of traditional mechanical presses and modern CNC-based solutions. Whether you are using a C Type Mechanical Power Press, a C Frame Hydraulic Press, or advanced CNC technologies like the CNC Press Brake Machine and CNC Hydraulic Shearing Machine, the goal remains consistent — to improve productivity, accuracy, and energy efficiency.

This blog explores why C-type press machines maintain their leading position in the sheet metal sector, how they compare to other systems, and what makes them the backbone of high-quality metal fabrication.

1. Understanding C-Type Press Machines

Contents

- 1 1. Understanding C-Type Press Machines

- 2 2. Why C-Type Press Machines Are the First Choice in Sheet Metal Industries

- 3 3. The Role of Advanced CNC Machines in Sheet Metal Processing

- 4 4. Key Advantages of Choosing C-Type Press Machines Over Others

- 5 5. Applications of C-Type Press Machines in the Sheet Metal Industry

- 6 6. Future of C-Type Press Machines in Modern Manufacturing

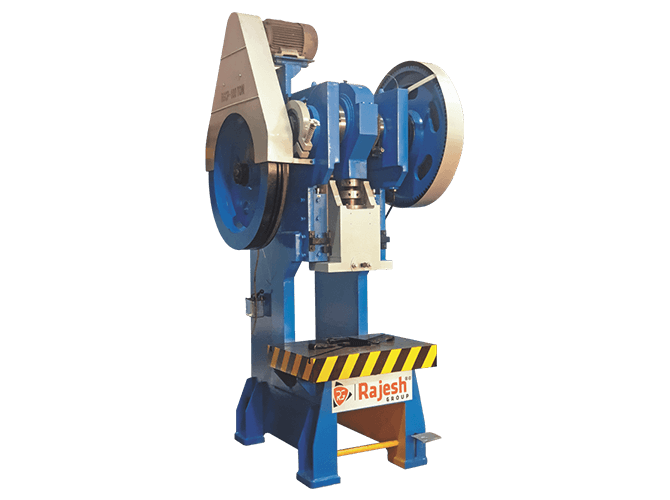

C-type press machines, named after their open “C” shaped frame, are uniquely designed to provide excellent accessibility, flexibility, and working convenience. Their structure allows quick loading and unloading of material, making them ideal for mass production and repetitive operations.

A C Type Mechanical Power Press typically uses mechanical motion for stamping, punching, blanking, bending, embossing, and deep drawing applications. These machines are built for strength and consistency, enabling manufacturers to maintain high output without compromising precision.

On the other hand, hydraulic versions like the C Frame Hydraulic Press offer improved stability, pressure control, and uniformity. They are essential for industries that need controlled force application from start to finish.

2. Why C-Type Press Machines Are the First Choice in Sheet Metal Industries

There are several reasons behind their popularity worldwide. Let’s explore them in detail.

A. Superior Accessibility

The open-front design of C-type machines allows wide access to the work area. Operators can easily position sheets, align dies, and make real-time adjustments.

This accessibility results in:

- Faster operations

- Reduced material handling

- Lower risk of operational errors

When compared to closed-frame machines, a C Frame Hydraulic Press provides unmatched operator convenience, especially for medium-duty work.

B. Versatility for Multiple Operations

C-type presses support various sheet metal operations, making them exceptionally versatile. Manufacturers can perform:

- Blanking

- Punching

- Coining

- Cutting

- Bending

- Deep drawing

Whether it’s a Hydraulic Press Brake Machine for heavy bending tasks or a Front Cylinder Press Brake Machine for a more compact working setup, C-type technology fits numerous use cases.

C. High Productivity and Speed

Mechanical presses like the C Type Mechanical Power Press are engineered for high-speed operations. They are widely used in industries that demand mass production with minimal downtime.

Their rigid frame and high-speed stroke make them perfect for:

- Automotive components

- Electrical stampings

- Kitchenware manufacturing

- Metal furniture industries

Hydraulic versions offer slightly slower cycles but provide exceptional force control — making them ideal for tasks that require accuracy rather than speed.

D. Precision and Consistency

Sheet metal industries value precision above everything else. Modern C-type presses integrate advanced technologies to ensure repeat accuracy and consistent pressure across every stroke.

When combined with automated systems and CNC controllers such as a CNC Press Brake Machine, factories get:

- Greater angle accuracy

- Predictable results

- Minimal manual intervention

E. Affordable Maintenance & Long Lifespan

C-type presses have fewer moving parts and a simpler design, making maintenance affordable and easier. Proper lubrication, alignment, and timely servicing ensure these machines operate for years without major issues.

Hydraulic-driven systems like the C Frame Hydraulic Press also offer long-term durability with minimal wear and tear when maintained properly.

3. The Role of Advanced CNC Machines in Sheet Metal Processing

Though traditional C-type presses hold a strong position, modern sheet metal industries now combine them with CNC systems for increased efficiency.

A. CNC Press Brake Machine: Precision Bending Power

A CNC Press Brake Machine uses automated programming to bend sheet metal accurately. Operators can input angles, dimensions, and bend sequences, and the machine handles everything with exceptional consistency.

Benefits include:

- Automatic back-gauge adjustment

- Perfect bending angles

- Reduced human error

- High repeatability

These machines complement C-type presses in factories that require bending alongside stamping and punching.

B. CNC Hydraulic Shearing Machine: Clean & Accurate Cuts

Cutting is one of the first steps in sheet metal processing, and a CNC Hydraulic Shearing Machine ensures precise cutting with minimal wastage. CNC shearing machines perform straight-line cuts effortlessly and consistently.

Their advantages:

- Smooth, burr-free sheet cuts

- Adjustable cutting angle

- High accuracy in repetitive cuts

- Faster production cycles

This machine works seamlessly with C-type press setups, creating an efficient production line.

C. Hydraulic Press Brake Machine: Power with Control

A Hydraulic Press Brake Machine provides strong bending power with hydraulic precision. Industries that handle thicker sheets or complex bending operations prefer hydraulic systems due to their stability and controlled pressure application.

Combined with C-type mechanical and hydraulic presses, these machines help manufacturers build a complete ecosystem for fabrication.

D. Front Cylinder Press Brake Machine: Compact & Powerful

The Front Cylinder Press Brake Machine is widely used in workshops with limited space. Its front-cylinder configuration offers:

- Excellent force distribution

- Easy maintenance

- Increased operator control

These machines are perfect for small to medium-sized industries looking for affordable and reliable bending technology.

4. Key Advantages of Choosing C-Type Press Machines Over Others

Let’s summarize why C-type press machines remain unbeatable:

1. Open Structure for Better Operation

Operators can easily manage materials, tools, and components during processing.

2. Robust Construction

The frame is strong enough to handle heavy-duty operations consistently.

3. Cost-Effective Solution

Compared to larger industrial presses, C-type machines require lower investment.

4. Perfect for Repetitive Jobs

Ideal for industries with high production requirements.

5. Easy Integration

C-type presses integrate smoothly with CNC machines, conveyors, feeders, and automation systems.

5. Applications of C-Type Press Machines in the Sheet Metal Industry

C-type presses are used extensively across industries such as:

- Automotive manufacturing

- Electrical and electronics

- Metal furniture

- Home appliances

- Agricultural tools

- Kitchenware production

- Hardware items

- Industrial machinery components

Their ability to handle thin, medium, and thick sheets makes them suitable for a wide range of applications.

6. Future of C-Type Press Machines in Modern Manufacturing

As industries move toward smart manufacturing, C-type presses are evolving too. Manufacturers now integrate digital controls, IoT monitoring, and energy-efficient hydraulic systems to ensure lower power consumption and improved performance.

C-type machines remain relevant because:

- They are scalable

- They support automation

- They provide excellent ROI

- They require minimal training

- They offer long-term reliability

Even as CNC machines grow in popularity, traditional press machines like the C Type Mechanical Power Press and C Frame Hydraulic Press continue to be essential in modern workflows.

Conclusion

C-type press machines have stood the test of time due to their exceptional performance, accessibility, durability, and operational flexibility. When paired with advanced technologies such as the CNC Press Brake Machine, CNC Hydraulic Shearing Machine, Hydraulic Press Brake Machine, and Front Cylinder Press Brake Machine, industries can achieve higher productivity and better-quality output.

For sheet metal processing companies aiming to improve production efficiency, reduce downtime, and maintain high precision across every operation, C-type press machines remain the first choice — and will continue to be for years to come.