The manufacturing world has entered a new era—speed and precision now define competitive success. High-speed CNC (Computer Numerical Control) machining is spearheading this revolution, allowing manufacturers to produce superior parts faster, more efficiently, and with greater accuracy than ever before. As global demand for complex products and rapid iteration soars, understanding the importance of high-speed CNC machining is crucial for any business aiming to thrive in tomorrow’s market.

What Is High-Speed CNC Machining?

High-speed CNC machining refers to the use of CNC machines equipped with advanced spindle motors, capable of speeds ranging from 15,000 RPM up to 60,000 RPM. Unlike traditional methods—limited to slow, heavy cutting passes—high-speed machining leverages rapid, lighter cuts, specialized tooling, and sophisticated control systems to remove metal with extraordinary efficiency. This escalation in processing power makes high-speed machining the go-to solution for industries that need tight tolerances and rapid development cycles, such as aerospace, automotive, medical devices, and high-tech manufacturing.

Core Benefits of High-Speed CNC Machining

Precision and Accuracy: Manufacturing Without Compromise

Modern industries demand micron-level accuracy. High-speed CNC machining is engineered to achieve dimensional tolerances as tight as 0.001 mm, even on intricate and delicate geometries. Enhanced control systems and high-resolution feedback mechanisms ensure every cut is as precise as the CAD model. The result is a consistent, repeatable process that slashes the risks of human error and produces components ready for direct assembly or final use.

Lightning-Fast Turnaround: Speed as a Strategic Weapon

Speed is no longer a luxury—it’s a necessity. High-speed CNC machining dramatically reduces lead times by increasing spindle and feed rates, streamlining toolpath strategies, and eliminating unnecessary manual interventions. This makes it possible to go from design to prototype or final part in days instead of weeks. In rapid prototyping and low-volume production, high-speed CNC machines transform bottlenecks into competitive advantages by slashing setup and cycle times.

Superior Surface Quality, Less Secondary Work

Surface finish matters—whether it’s a visual design part or a high-stress aerospace component. High-speed machines deliver exceptional finishes, often achieving surface roughness as low as Ra 0.1–0.4 µm, which means reduced or eliminated grinding and polishing. By minimizing tool deflection and vibration, high-speed CNC machining ensures every part not only looks better but performs more reliably in service.

Essential Features Empowering High-Speed Machining

- Advanced Toolpath Optimization: Techniques like trochoidal milling and adaptive clearing allow for continuous machining, minimizing tool wear and material wastage while speeding up production cycles.

- Real-Time Monitoring and Adaptive Control: Integrated sensors adjust speeds, feeds, and tool paths based on cutting conditions. This real-time optimization maintains dimensional accuracy and extends tool life.

- Thermal Compensation: Cutting at high speeds generates heat, risking material distortion. Sophisticated temperature compensation systems ensure stability, so quality stays high across long runs.

- Seamless CAD-CAM Integration: High-speed CNC machining enables direct processing from digital designs, simplifying changes and reducing costly retooling and manual setup.

The Cost & ROI Equation

Traditional machining often incurs high labor, maintenance, and rework costs due to inefficiency and human involvement. High-speed CNC machining, by contrast, minimizes manual intervention through automation and robot integration, enabling 24/7 operation and lights-out manufacturing. This boosts ROI via:

- Reduced material waste thanks to smarter tool engagement

- Lower labor costs due to automation and unattended running

- Less tooling wear, extending equipment lifespan

- Decreased need for costly secondary finishes

High-speed CNC machining pays for itself quickly, especially in high-mix, low-volume environments or when time-to-market is paramount.

Real-World Applications: Where High Speed Makes the Difference

- Aerospace: Impellers, turbine blades, and lightweight frames, where tolerance and time-to-market are vital

- Medical Devices: Complex implants and surgical instruments, demanding repeatability and perfect finishes

- Automotive: Engine components, dashboards, and alloy wheels—benefiting from rapid prototyping and streamlined mass production

- Electronics: Intricate housings, connectors, and sensor mounts requiring sub-millimeter accuracy

High-speed machining also shines when working with difficult materials like Inconel, titanium, and carbon fiber composites—materials that are otherwise slow and costly to process.

Latest Industrial Trends: The Future is High-Speed, Automated, and Intelligent

2025 and beyond are set to witness key trends reshaping CNC machining:

- AI-Driven Optimization: Predictive maintenance, real-time error detection, and process tweaks guarantee uptime and zero-defect manufacturing.

- Hybrid Manufacturing: The integration of additive (3D printing) and subtractive (CNC) methods for unmatched design flexibility and efficiency.

- Advanced Tooling Materials: Carbide, ceramic, and diamond coatings withstand ultra-high speeds and demanding applications.

- Eco-Conscious Practices: New designs focus on energy efficiency and waste minimization, vital in a world prioritizing sustainability.

- Localized Manufacturing: Distributed, on-demand production minimizes supply chain risks and cuts lead times for critical industries.

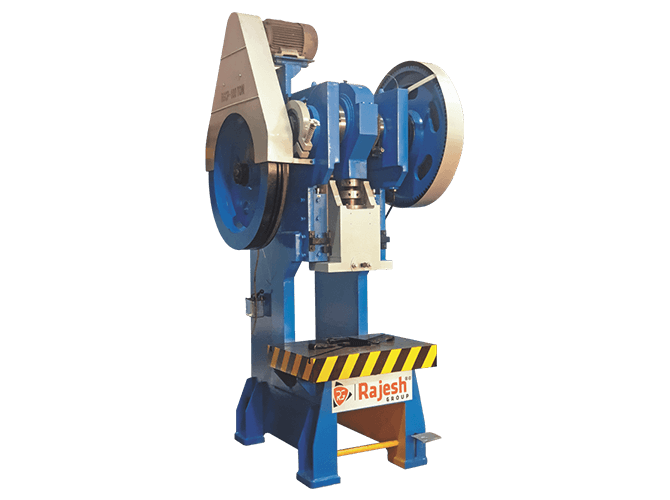

The Rajesh Machine Tools Advantage

As a premier CNC machinery provider, Rajesh Machine Tools brings decades of experience and a deep commitment to supporting manufacturers in their digital transformation. Our high-speed CNC machining centers embody the frontier of production excellence—combining robust construction, intuitive interfaces, state-of-the-art controls, and dedicated post-sales support to ensure success for Indian and global manufacturers alike.

Conclusion: High-Speed CNC Machining—Your Strategic Edge

The advantages of high-speed CNC machining are clear—unmatched speed, supreme accuracy, cost efficiency, and the capacity to tackle tomorrow’s manufacturing challenges today. In a marketplace where speed, complexity, and innovation are non-negotiable, investing in high-speed CNC technology is not merely an upgrade—it’s the core of future-ready manufacturing.

If you’re ready to boost productivity, lower costs, and deliver the quality your customers demand, the time for high-speed CNC machining is now. With Rajesh Machine Tools at your side, you’re not just embracing technology but driving the next wave of manufacturing excellence.