Blog

Top C-Type Mechanical Power Press Manufacturer Rajkot

Rajkot isn’t just a city—it’s the beating heart of India’s machine tool industry, where decades of craftsmanship converge with cutting-edge engineering. For starter entrepreneurs, this Gujarat powerhouse offers more than machines; it delivers the precision, reliability, and innovation that transform metal into opportunity. With over 40 years of industrial evolution, Rajkot has emerged as the epicenter of C-type mechanical power press manufacturing, where names like Rajesh Machine Tools don’t just build equipment—they engineer the backbone of global manufacturing.

Understanding the C-Type Mechanical Power Press: Design and Functionality

Contents

- 1 Understanding the C-Type Mechanical Power Press: Design and Functionality

- 2 The Evolution of Power Press Technology in Rajkot

- 3 Rajesh Machine Tools: Setting the Benchmark in C-Type Mechanical Power Presses

- 4 Engineering Strength: Frame Construction, Components, and Precision

- 5 Versatility and Application Spectrum of C-Type Presses

- 6 Quality Assurance, Safety, and After-Sales Support

- 7 Empowering Industry: Rajkot’s Role in National and Global Manufacturing

- 8 Conclusion: Choosing Rajkot’s C-Type Mechanical Power Press for Future-Ready Manufacturing

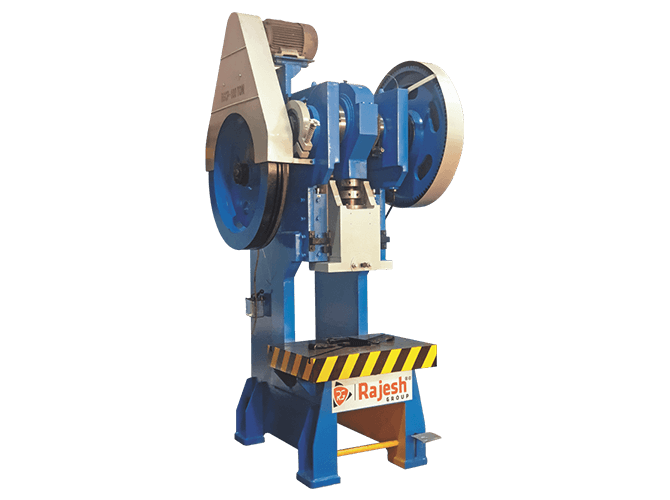

The Anatomy of Precision

At its core, the C-type mechanical power press is a masterpiece of functional design. Its iconic C-shaped frame—open-backed for unrivaled workpiece access—transforms rotational energy into crushing force. Picture this: a motor-driven flywheel spins a hardened alloy steel crankshaft, which slams the ram downward at speeds up to 1,200 strokes per minute. The result? Clean cuts, flawless bends, and stamped shapes with tolerances tighter than a human hair.

What sets Rajkot’s C-type presses apart is their ruthless efficiency. “The clutch gives continuous stroke for mass production,” explains a veteran engineer, referencing the pin/rolling key-type clutch that eliminates slippage. Unlike hydraulic systems, these mechanical beasts convert energy directly—no fluid dynamics, no pressure loss. Just raw, unfiltered power where every joule of energy translates to profit.

The Evolution of Power Press Technology in Rajkot

From Workshops to Global Dominance

Rajkot’s journey began in the 1980s, when gritty workshops started retrofitting imported machines. Today, it’s a export powerhouse shipping to 7+ countries, including Indonesia and Oman. The transformation? A blend of ancestral metallurgy wisdom and relentless innovation. Early press frames were crude cast iron; now, they’re fabricated from IS-2062 graded steel, stress-relieved in furnaces and machined to micron-level precision.

Zinger: While Germany invented the power press, Rajkot perfected it for the real world—where dust, heat, and 24/7 operation are non-negotiables.

Rajesh Machine Tools: Setting the Benchmark in C-Type Mechanical Power Presses

The Gold Standard

Rajesh Machine Tools isn’t just a manufacturer—it’s a 40-year legacy of redefining metalwork. Their C-type presses (3–250 tons capacity) are the industry’s workhorses, chosen by automotive giants and aerospace startups alike. Why? “Our ability to innovate and adapt to industry demands has allowed us to become one of the top power press manufacturers,” states their engineering team. From pneumatic feeders for automation to electronic safety systems, Rajesh presses are modular, future-proof, and brutally reliable.

Engineering Strength: Frame Construction, Components, and Precision

Built for War, Not Just Work

Dive into the engineering, and you’ll find why Rajkot’s presses outlast competitors:

- Frame: Fabricated from IS-2062 rolled steel, cross-ribbed and stress-relieved. “Proper alignment is ensured by machining,” ensuring the frame won’t warp even after 10,000 cycles.

- Crank Shaft: Special alloy steel, ground to optical precision and nested in bronze bushes for frictionless operation.

- Flywheel: High-grade cast iron, balanced like a Swiss watch to store/release energy without vibration.

- Gears: Steel-cast, precision-hobbed teeth that mesh like silk.

| Component | Material/Feature | Impact |

| Frame | IS-2062 steel, stress-relieved | Zero deflection under 250-ton loads |

| Clutch | Pin/rolling key-type | Continuous strokes for mass production |

| Lubrication | Shot lubrication system | 30% longer component life |

Zinger: In Rajkot’s presses, even the lubricant is applied with sniper-like precision—hand-pumped to eliminate waste.

Versatility and Application Spectrum of C-Type Presses

One Machine, A Thousand Possibilities

Rajkot’s C-type presses are the Swiss Army knives of fabrication. Need to punch 5mm steel for tractor parts? Set the ram to 100 tons. Crafting delicate aerospace brackets? The adjustable stroke (up to 335mm) handles it. Industries from automotive (70% of global press demand) to construction rely on these machines for:

- Stamping emblem logos onto luxury car grilles

- Punching ventilation slots in server racks

- Bending structural beams for skyscrapers

“The open-back design enables operators to load and unload workpieces efficiently,” notes a plant manager, highlighting how Rajkot’s designs shave 15 seconds off every cycle—translating to 4,000 extra parts per month.

Quality Assurance, Safety, and After-Sales Support

No Compromise, No Excuses

Every Rajesh press undergoes a baptism by fire: performance testing under 110% load, precision validation with laser alignment, and corrosion resistance trials. Safety isn’t an add-on—it’s embedded via two-hand controls, electronic knockouts, and light curtains that halt operation if a finger strays near the die.

After-sales? Rajkot’s manufacturers deploy technicians within 48 hours, armed with genuine spares and training modules. “We prioritize automation and smart technologies,” says Rajesh’s service head, offering predictive maintenance alerts that prevent 92% of unplanned downtime.

Empowering Industry: Rajkot’s Role in National and Global Manufacturing

The Silent Engine of Progress

Rajkot’s presses don’t just bend metal—they bend economic curves. With 33+ shipments to 7 countries annually, the city fuels industries from Qatar’s oil pipelines to Indonesia’s motorcycle hubs. The global press machine market ($0.5B in 2022 → $0.8B by 2030) leans heavily on Rajkot’s trifecta: cost efficiency (30% cheaper than European counterparts), customization, and brute durability.

Zinger: While Silicon Valley codes apps, Rajkot forges the physical world—one precision-stamped part at a time.

Conclusion: Choosing Rajkot’s C-Type Mechanical Power Press for Future-Ready Manufacturing

For entrepreneurs, selecting a Rajkot-built C-type press isn’t a purchase—it’s a strategic alliance with excellence. Rajesh Machine Tools epitomizes this: 40 years of honing presses that blend artisan craftsmanship with AI-ready automation. In a world where manufacturing is the ultimate competitive edge, Rajkot delivers more than machines; it delivers certainty in an uncertain world. So when your startup needs to punch above its weight, remember: Rajkot’s presses don’t just shape metal—they shape futures.