Blog

Hydraulic Power Press Machine in India

Looking to enhance your manufacturing capabilities? Hydraulic power press machines in India offer precision, efficiency, and versatility for various industries. Discover how these machines can revolutionize your production processes, reduce operational costs, and increase safety in your facility.

Understanding the Role of Hydraulic Power Press Machines in India’s Manufacturing Sector

Contents

- 1 Understanding the Role of Hydraulic Power Press Machines in India’s Manufacturing Sector

- 2 Technical Specification

- 3 The Mechanics Behind Hydraulic Power Press Machines

- 4 Applications Across Industries

- 5 Benefits of Using Hydraulic Power Press Machines

- 6 Environmental and Economic Impact

- 7 The Future of Manufacturing with Hydraulic Presses

- 8 Challenges in Maintenance and Operation

- 9 Conclusion

Hydraulic power press machines play a pivotal role in India’s manufacturing landscape. As a staple in factories across the nation, these machines mould, press, or compact materials with incredible precision and efficiency.

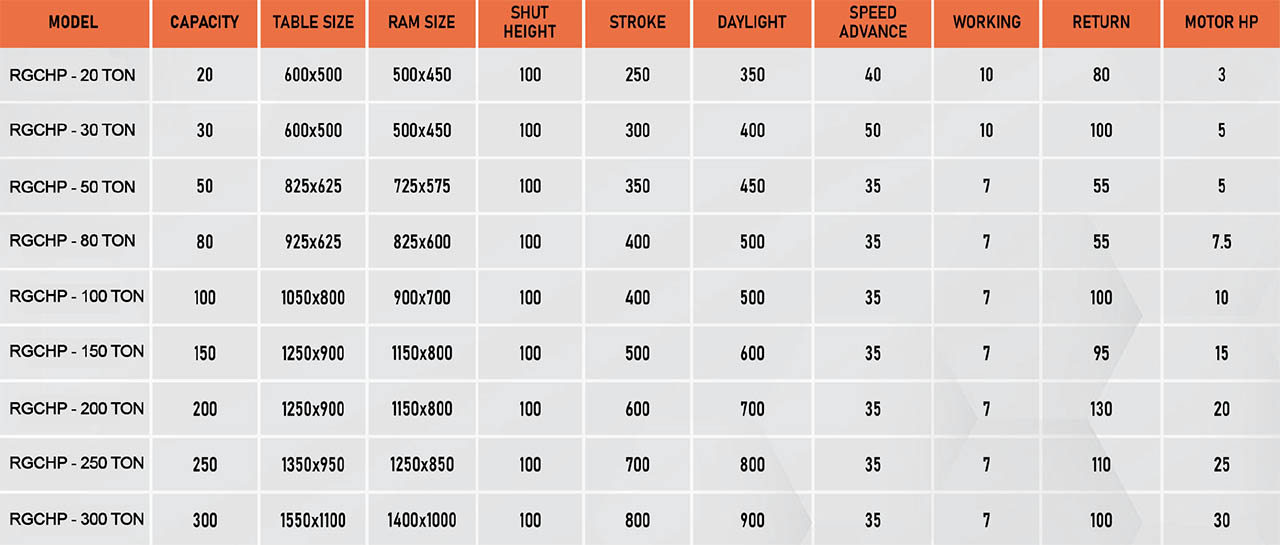

Technical Specification

The Mechanics Behind Hydraulic Power Press Machines

A hydraulic power press uses a hydraulic cylinder to generate a compressive force. Unlike mechanical presses, these rely on hydraulic fluid to transfer energy, and this fluid movement results in smoother, controllable operations. Manufacturers favour this machine for its ability to work with various materials, including metals, plastics, and composites.

Applications Across Industries

From automotive to metalwork and electronics, hydraulic presses are versatile. In the automotive sector, they are essential for sheet metal forming, assembling operations, and deep drawing. Their reliability and power make them ideal for creating complex parts in aerospace and electronic goods manufacturing as well.

Benefits of Using Hydraulic Power Press Machines

Hydraulic power presses offer significant advantages over their mechanical counterparts. They provide:

- Enhanced Control: Operators can adjust the press force and stroke according to the task.

- Greater Capacity: These machines handle extremely high loads, making them suitable for heavy-duty operations.

- Versatility: With the ability to work on various materials and perform different manufacturing tasks, they are invaluable to any production line.

- Safety Features: Modern hydraulic presses are equipped with safety measures to protect operators from common hazards associated with high-force machinery.

Environmental and Economic Impact

Adopting hydraulic power press machines not only boosts production efficiency but also promotes sustainability. These machines often require less energy than older mechanical presses and contribute to lower operational costs over time. Their precise operation reduces material waste, enhancing both economic and environmental efficiency.

The Future of Manufacturing with Hydraulic Presses

As technology advances, so does the functionality of hydraulic presses. Modern adaptations include increased automation and better integration with other manufacturing systems. This evolution ensures hydraulic presses will remain a cornerstone in manufacturing, driving production lines towards greater productivity and innovation.

Challenges in Maintenance and Operation

While hydraulic presses are robust, they do require regular maintenance to prevent downtime. Ensuring they operate at peak efficiency involves routine checks and fluid changes. Additionally, training for operators is essential to handle these sophisticated machines safely and effectively.

Conclusion

Hydraulic power press machines are more than just equipment; they are a critical component of the manufacturing backbone in India. With their ability to adapt to various manufacturing needs and push the limits of what can be achieved in industrial production, their role is undeniable. As industries strive to meet higher standards of precision and efficiency, these machines will continue to be a key player.

Read About: Mechanical Power Press Machines Manufacturers in India

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.