Blog

NC Shearing Machine in India

NC Shearing Machine in India: Precision and Efficiency

Contents

NC shearing machines are vital in the metal fabrication industry. They cut sheets of metal accurately and efficiently. These machines use numerical control (NC) technology. This ensures precision, speed, and repeatability in every cut. In India, the demand for these machines is on the rise. The country’s growing manufacturing sector drives this trend.

Understanding the Technology

NC shearing machines work by automating the cutting process. Operators input precise measurements into the machine. The machine then follows these commands to cut metal sheets. This reduces human error significantly. The technology behind NC shearing machines includes powerful software. This software ensures the machine performs consistently.

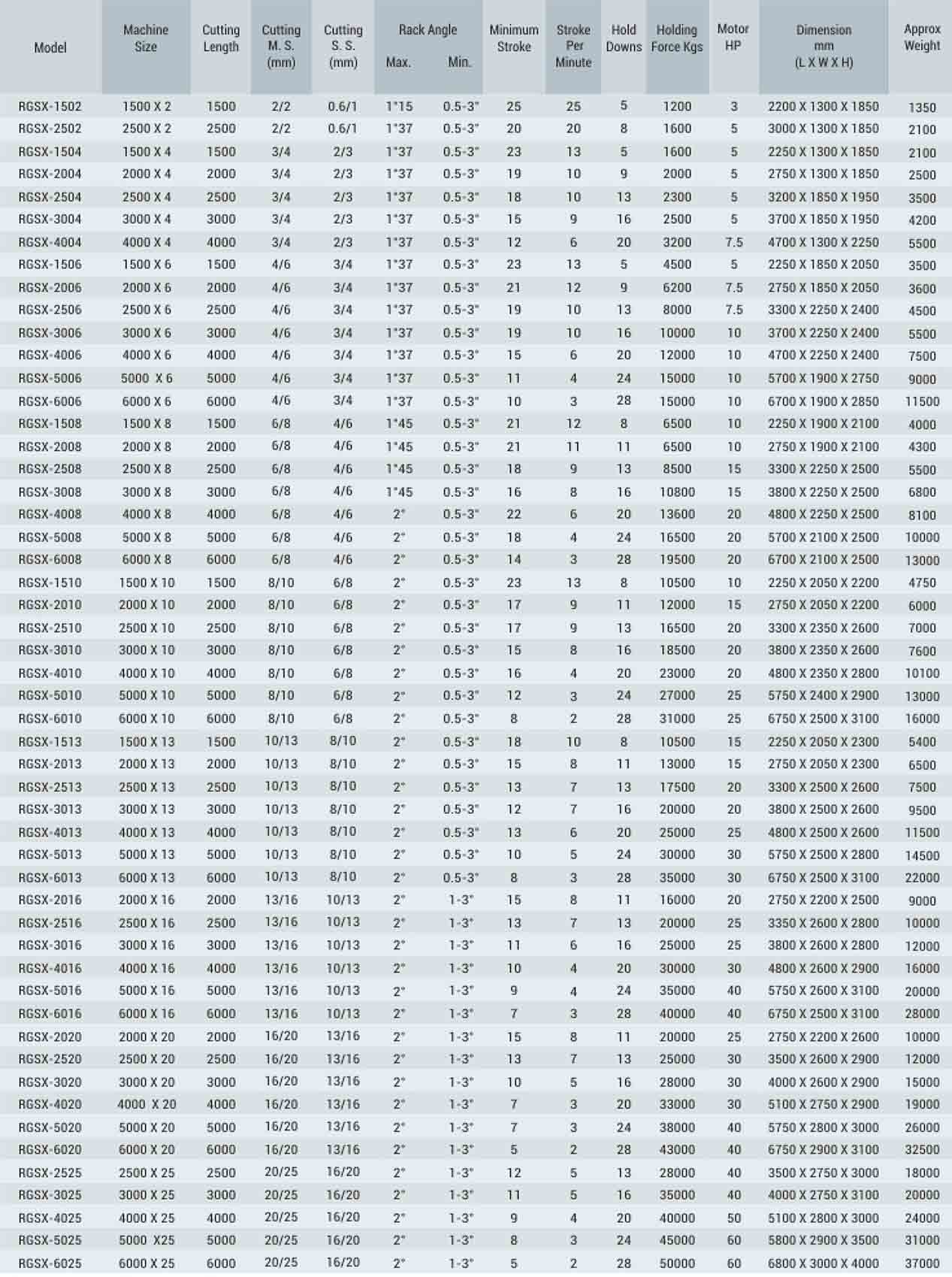

Technical Specification

Benefits of NC Shearing Machines

NC shearing machines offer several benefits:

- Precision Cutting: They provide accurate cuts every time. This is crucial for maintaining quality in manufacturing.

- Efficiency: These machines can handle large volumes quickly. This boosts overall productivity.

- Consistency: With NC technology, every cut is the same. This uniformity is important for mass production.

- Reduced Waste: Precise cutting means less material wastage. This saves money and resources.

- Ease of Use: Modern NC shearing machines are user-friendly. Operators can learn to use them quickly.

- Versatility: They can cut various materials, including steel and aluminium.

Applications of NC Shearing Machines

NC shearing machines are used across different industries. These include automotive, construction, and aerospace. In the automotive industry, they cut metal sheets for car parts. In construction, they help in making beams and other structural elements. Aerospace companies use them to cut materials for aircraft components.

Features of NC Shearing Machines

Modern NC shearing machines come with advanced features:

- Touchscreen Controls: These make the machine easy to operate.

- Automatic Blade Gap Adjustment: This feature ensures optimal cutting performance.

- Programmable Back Gauge: It allows for precise control over the cut length.

- Safety Features: These include emergency stop buttons and protective barriers.

Importance of Maintenance

Regular maintenance is crucial for NC shearing machines. Proper upkeep ensures the machine runs smoothly. This includes regular cleaning, lubrication, and checking for wear and tear. Scheduled maintenance can prevent costly breakdowns. It also extends the lifespan of the machine.

Future of NC Shearing Machines in India

The future looks promising for NC shearing machines in India. The country’s manufacturing sector is expanding. This growth drives demand for advanced machinery. Companies are investing in modern equipment to stay competitive. This includes NC shearing machines. Technological advancements will further enhance these machines. We can expect more automation and smarter features.

Conclusion

NC shearing machines are transforming the metal fabrication industry. Their precision, efficiency, and reliability make them indispensable. In India, their importance is growing in the manufacturing sector. Investing in these machines is a smart move for any company. It ensures high-quality production and boosts overall productivity. Regular maintenance and updates will keep them running efficiently. The future of NC shearing machines in India is bright.

Read About: CNC Shearing Machine in India

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.