Blog

NC Press Brake Machine in India

NC Press Brake Machine in India

Contents

Metal fabrication demands precision and reliability. That’s where NC Press Brake Machines shine. These machines ensure accurate bending and shaping of metal sheets. In India, the demand for these machines is growing. Let’s delve into why RG-NX NC Front Cylinder Press Brake Machines are crucial for the metal fabrication industry and how they transform production.

What is an NC Press Brake Machine?

An NC (Numerical Control) Press Brake Machine is a metalworking tool designed for bending metal sheets. With a computer-aided control system, it precisely manages the bending angle and pressure. The NC technology offers a simplified and efficient solution compared to manual bending, making it indispensable for industries requiring high precision.

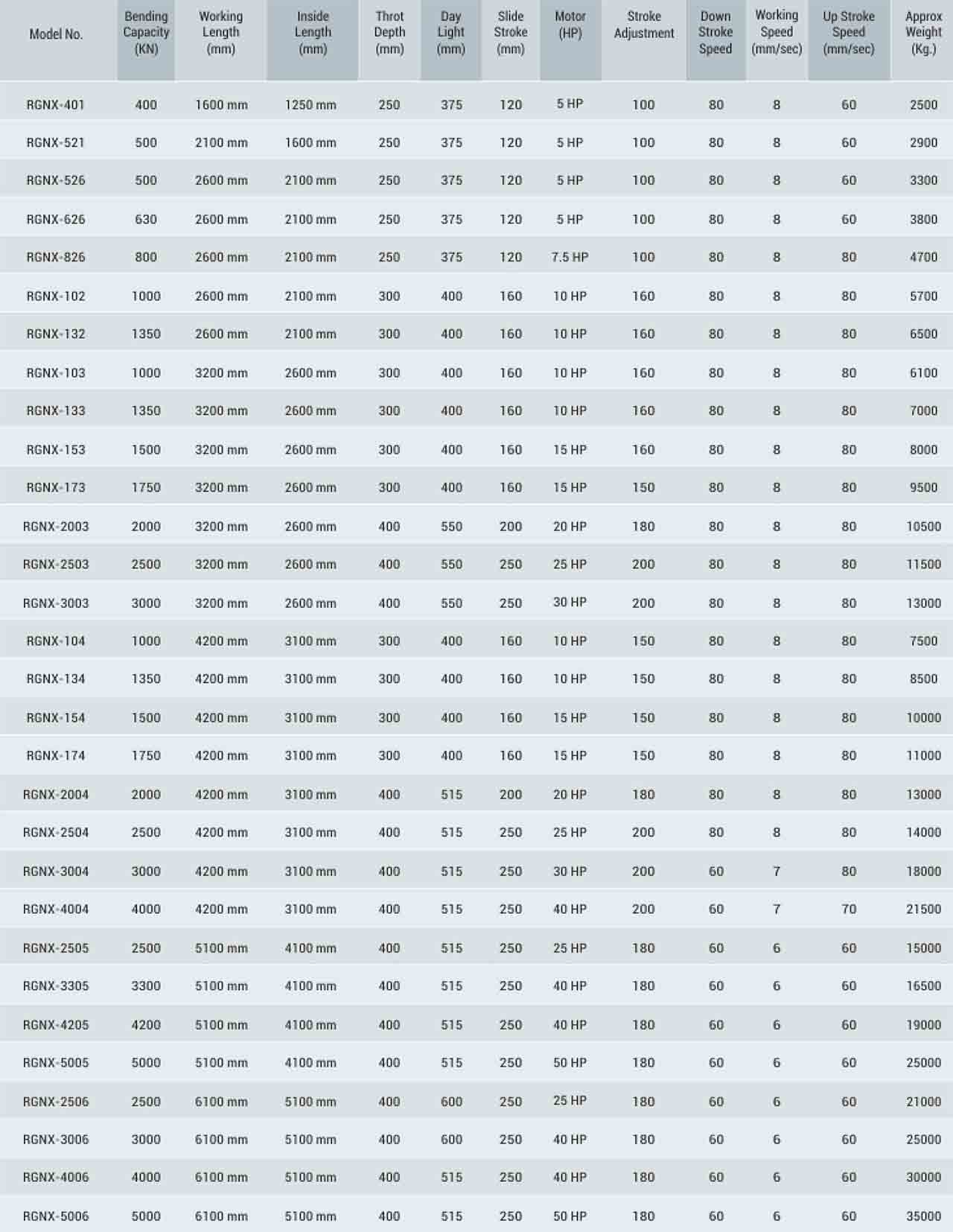

Technical Specification

Key Benefits of NC Press Brake Machines

- Accuracy and Precision: The NC control system ensures repeatable precision, reducing human error.

- Productivity Boost: Automated settings lead to quicker setup times and faster production cycles.

- Flexibility: Suitable for bending diverse materials, these machines can handle various sheet sizes and thicknesses.

- Energy Efficiency: Modern NC Press Brake Machines use energy-saving technologies, minimizing power consumption.

- Reduced Waste: Precise bending minimizes material wastage, contributing to cost savings.

Applications in the Industry

NC Press Brake Machines are versatile and used in several industries:

- Automotive: Creating metal components like chassis, body panels, and exhaust parts.

- Aerospace: Fabricating aircraft structural parts with precision and consistency.

- Construction: Producing metal beams, panels, and other construction elements.

- Furniture: Forming metal frames and parts for office and home furniture.

- HVAC: Shaping ducts, pipes, and HVAC components.

Why NC Press Brake Machines Stand Out

Their advanced control systems enable high customization for each job. Operators can program exact bend angles and sequences, leading to consistent results across multiple runs. Their adaptability lets manufacturers quickly switch between different projects, saving time and reducing operational costs.

Future of NC Press Brake Machines

The future is bright for NC Press Brake Machine in India. With the industry leaning towards automation, these machines provide an ideal stepping stone for factories aiming to upgrade their operations. Upcoming trends include:

- Integration with CAD/CAM Software: Allowing for a seamless transition from design to production.

- IoT Connectivity: Real-time monitoring and diagnostics for predictive maintenance.

- Enhanced Safety Features: Minimizing operator risk while maintaining production speeds.

Conclusion

NC Press Brake Machines are revolutionizing metal fabrication in India. Their precision, efficiency, and versatility make them an essential tool for manufacturers seeking high-quality bending solutions. As industries embrace automation and modern technology, these machines will continue to drive growth and efficiency in metalworking.

Read About: Hydraulic Shearing Machine in India

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.