RG PLUS Series

RG PLUS Series

The RG PLUS series CNC Press Brake Machine is built for fabricators who demand precision without compromise. Designed for speed, energy efficiency, and consistent accuracy, this machine handles everything from intricate components to high-load structural parts — all while minimizing cost and maximizing uptime.

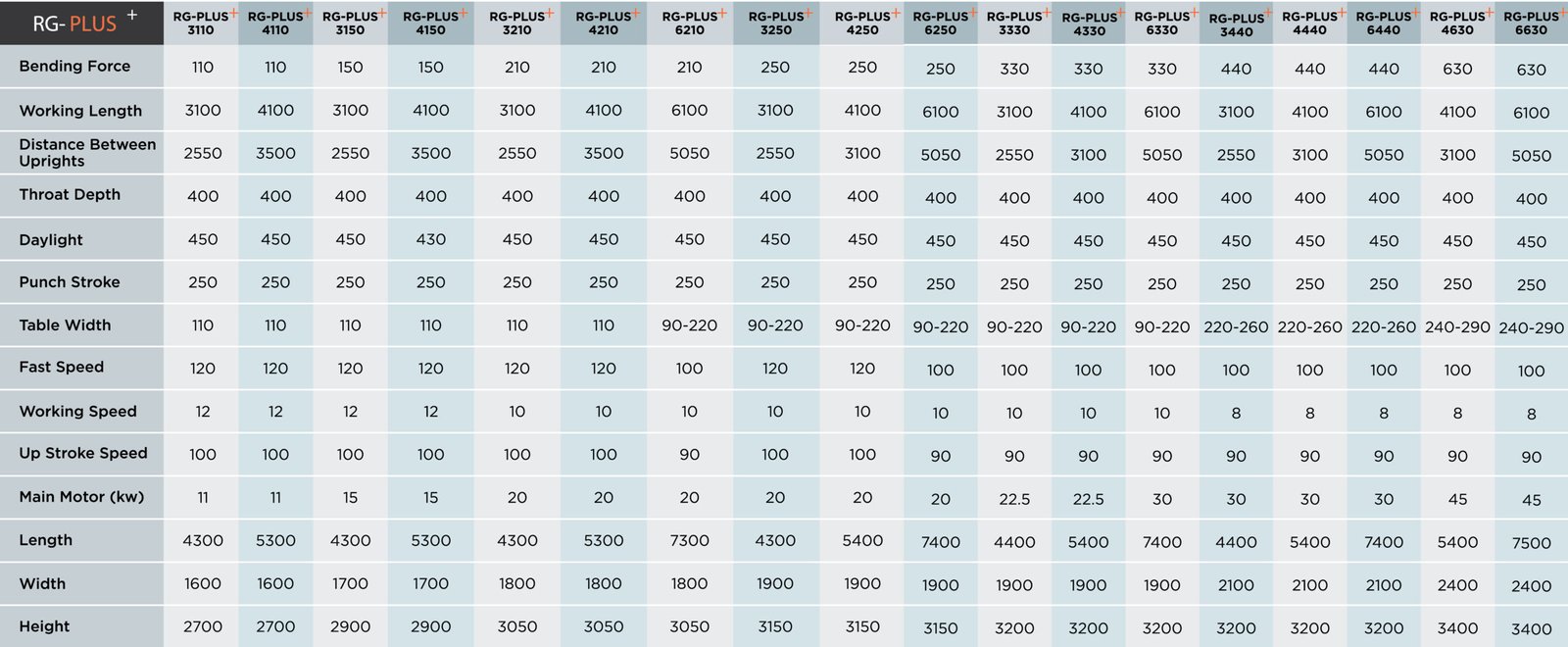

Technical Specification

Why Choose the RG PLUS Series CNC Press Brake Machine

Fast, Reliable Production

Beam speeds up to 160 mm/sec and pressing speeds of 10–12 mm/sec ensure faster cycles and shorter lead times.

Energy Efficiency at the Core

Save up to 45% in power consumption through an optimized hydraulic system designed for sustainability and cost savings.

Built for the Long Run

Fabricated from IS:2062 grade steel and precision-machined for long-term reliability under continuous operation.

Exceptional Accuracy & Repeatability

3+1 axis (Y1, Y2, X, R) automation delivers consistent results — bend after bend, job after job.

Swiss CNC Intelligence

Equipped with CybTouch 8PS (CYBELEC, Switzerland) or ESA S630 touchscreen controller for fast programming and visual sequence management.

Silent and Smooth Operation

Built for operator comfort with ultra-low noise and vibration levels.

Key Features at a Glance

3+1 Axis Control System

- Y1, Y2 synchronized cylinders

- X-axis back gauge with ±0.01 mm accuracy

- R-axis programmable height adjustment

- Precision CNC bending for small and complex parts

Rigid Frame & Precision Engineering

- Constructed from IS:2062 grade steel

- Frame machined on the floor boring machine for single-reference alignment

- Rigid upper beam guided by 12-point roller bearings for zero deflection

Energy-Saving Hydraulic System

- Smart hydraulic controls activate only when needed

- Significant reduction in heat generation and power consumption

- Stable oil temperature = consistent bending accuracy

User-Friendly CNC Interface

- Touchscreen controller for intuitive operation

- Rapid job setup and storage for repeat batches

- Visual bend programming and simulation

Tooling & Sheet Support

- Quick-release punch clamps

- Sliding front sheet supports with LM guides

- Ball screw–driven back gauge for smooth, silent movement

Applications Across Industries

- Automotive : High-volume, high-precision bending for brackets, chassis, panels

- Aerospace : Accurate forming of lightweight alloys and titanium components

- Construction : Heavy-gauge sheet metal for structural frameworks and cladding

- General Fabrication : From prototypes to production — consistent, versatile results

This machine adapts seamlessly to high-mix, high-precision production environments.

Outperforms the Competition

Compared to models from PrimaPress, ADHMT, KRRASS, or ACCURL, the Splendid Series offers:

- Superior energy savings - up to 45% lower consumption

- Stronger frame rigidity for consistent performance under full load

- Faster beam and pressing speeds for higher output

- Tailored configurations for real-world needs — not generic imports

Backed by a leading Indian manufacturer, this machine gives you global quality with local trust and service.

Additional Benefits

- Low Maintenance : Durable design minimizes downtime and reduces service costs

- Tooling Flexibility : Fast changeovers and compatibility with multiple die setups

- Advanced Support System : Front sheet supports, CNC back gauge, and LM guides for operator ease

Whether you’re expanding capacity or upgrading capability, the Splendid Series is built to deliver.

Why Fabricators Trust Rajesh CNC

- Decades of CNC Engineering Excellence Our in-house R&D, advanced machining capabilities, and global exports reflect our commitment to innovation and quality.

- End-to-End Support From machine setup to operator training, Rajesh CNC offers reliable after-sales support.

- Made in India, Trusted Globally Serving clients across India, the Middle East, and beyond with machines built for long-term value.

Technical Characteristics

- Hydraulic System : HOREIBGER - HAWE make hydraulic system with servo valve and prefill block

- X Axis : 650 mm travel with AC servo drive and ball screw movement

- R Axis : Automatic / Manual adjustment, 200 mm travel (Selected Axis Option)

- Z Axis : Manual adjustment with linear guide movement (Selected Axis Option)

- Front Sheet Support Arms : Mounted on LM guide – sliding type (2 Nos.)

- Backgauge Fingers : 2 Nos.

- Anti-Deflection System : CNC anti-deflection table with point-to-point adjustment using European technology

- Electrical : Schneider make electrical panel with integrated safety features and servo drive

- Axis Motor Type : Servo motor with inbuilt cooling fan (Auxiliary Axis)

- Tooling : Standard Tooling

Controller Options

- CYBELEC : CYB Touch 8PS / 12PS / 19PS

- STEP AUTOMATION : ROCK 12 PLUS / 15 PLUS / 17 PLUS