RG PLUS HD Series

RG PLUS HD Series

The RG PLUS HD Series CNC Press Brake Machine brings next-level bending performance to the fabrication floor. Designed for exacting accuracy, smooth control, and optimized energy use, this machine is your go-to solution for advanced sheet metal bending — whether you’re handling automotive brackets, aerospace components, or structural parts.

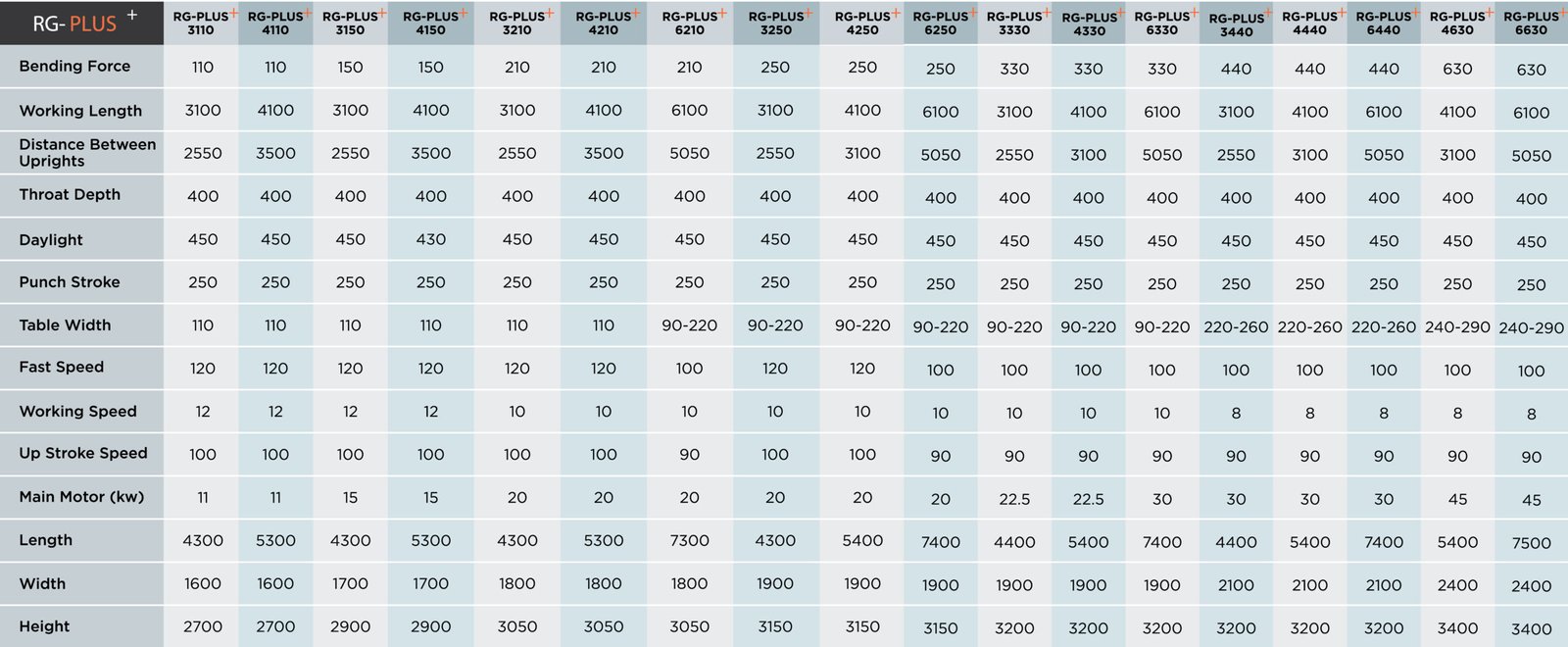

Technical Specification

Why Choose the RG PLUS HD Series CNC Press Brake

Servo-Hydraulic Precision

Y1 & Y2 axes controlled by a servo motor + hydraulic pump combo for precise repeatability.

High-Speed Cycles

Beam speeds up to 220 mm/sec and pressing speeds up to 16 mm/sec reduce cycle time significantly.

Energy Savings Up to 50%

Smart hydraulic system cuts power consumption nearly in half — saving costs and reducing environmental impact.

Swiss CNC Technology

Equipped with a CybTouch 8PS controller from CYBELEC (Switzerland) for intuitive programming and visual bend sequencing.

Silent, Stable, and Smooth

Engineered for ultra-low noise, smooth motion, and consistently accurate bending across production runs.

Key Features at a Glance

Advanced Axis Control

- Y1, Y2, and X-axis automation

- Fast, programmable back gauge for consistent part accuracy

- Stable positioning even during complex or repeated bends

User-Friendly CNC Controls

- CybTouch 8PS interface

- Quick setup with graphical programming

- Ideal for both experienced operators and new users

Servo-Driven Hydraulic System

- Energy-on-demand system reduces heat and oil use

- Lower hydraulic oil volume = cleaner, cooler, greener operation

- Consistent oil temperature improves accuracy

Low Maintenance, High Uptime

- Fewer moving parts and smarter diagnostics

- Built to reduce wear, downtime, and maintenance effort

Rigid Frame Construction

- IS:2062 steel frame, ultrasonically tested

- Machined on a floor boring machine for single-reference precision

- Upper beam guided by 12-point roller bearings — zero deflection, no vibration

Applications Across Industries

- Automotive : Precise panel, bracket, and frame component bending

- Aerospace : Lightweight alloy and titanium bending to tight tolerances

- Construction : Fast, accurate forming for steel structures and building panels

- General Fabrication : Efficient across small-scale custom jobs and large batch production

The RG PLUS HD Series integrates effortlessly into your existing production line — flexible, scalable, and reliable.

Outperforms the Competition

Compared to similar machines from PrimaPress, ADHMT, KRRASS, and ACCURL, the RG PLUS HD Series delivers:

- Higher Energy Efficiency - Saves 45–50% power over conventional models

- Stronger Frame Rigidity Outlasts lighter competitor frames under industrial load

- Faster Output Up to 220 mm/sec beam speeds for high-volume environments

- Smarter Customization Tailored tonnage, length, and control configurations

Backed by Rajesh CNC’s proven engineering and local support network — giving you more control over price, delivery, and service.

Additional Benefits

- Tooling Flexibility : Supports a wide range of V-dies and punches

- LM-Guided Sheet Supports : Smooth, operator-friendly front loading

- Smart Diagnostics : Monitors performance to prevent disruptions

- Reduced Oil Usage : Lowers environmental footprint and running costs

Whether you’re expanding capacity or upgrading capability, the Splendid Series is built to deliver.

Why Fabricators Choose Rajesh CNC

- 20+ Years of Experience Serving India's leading manufacturers

- Custom-Built Machines Configured to match your operations

- Global Reach with Local Service Exported across the Middle East, Africa, and Asia

- Unmatched Value CNC-grade performance at competitive pricing

Technical Characteristics

- Hydraulic System : HOREIBGER - HAWE makes a hydraulic system with a servo valve and a prefill block

- X Axis : 650 mm travel with AC servo drive and ball screw movement

- R Axis : Automatic / Manual adjustment, 200 mm travel (Selected Axis Option)

- Z Axis : Manual adjustment with linear guide movement (Selected Axis Option)

- Front Sheet Support Arms : Mounted on LM guide – sliding type (2 Nos.)

- Backgauge Fingers : 2 Nos.

- Anti-Deflection System : CNC anti-deflection table with point-to-point adjustment using European technology

- Electrical Panel : Schneider make electrical panel with integrated safety features and servo drive

- Axis Motor Type : Servo motor with inbuilt cooling fan (Auxiliary Axis)

- Tooling : Standard Tooling

Controller Options

- CYBELEC : CYB Touch 8PS / 12PS / 19PS

- STEP AUTOMATION : ROCK 12 PLUS / 15 PLUS / 17 PLUS