RG MAXX BEND Series

RG MAXX BEND Series

RG MAXX BEND Series CNC Press Brake Machine

Built for demanding bending applications, the RG MAXX BEND Series CNC Press Brake Machine delivers unmatched speed, efficiency, and accuracy — all while consuming less power and requiring minimal maintenance. Whether you’re handling small-scale jobs or industrial-scale production, the RG MAXX BEND Series adapts, performs, and exceeds expectations.

Features

- DHD with real-time control of approach speed.

- Completely closed-loop system

- Fully controlled approach speed through the pump.

- Full decompression control for precise springback calculation.

- Speed, position, and force controlled the servo pump

- High positioning of the ram was achieved without the use of a Proportional valve

- High Bending Accuracy +/-0.005mm

- Very fast approach, bending, and return 250-20-250 mm/s

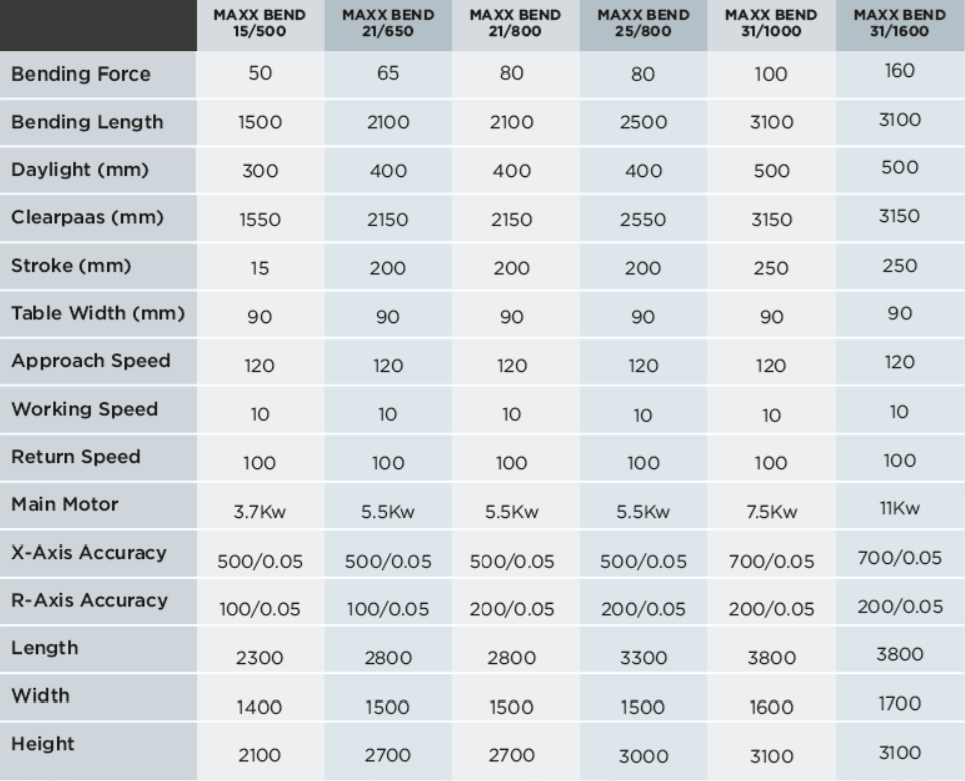

Technical Specification

Why Choose the RG MAXX BEND Series

Servo-Hydraulic Precision

Servo motor and hydraulic pump combination controls Y1 and Y2 axes with outstanding accuracy.

Faster Bending Cycles

Beam speeds up to 220 mm/sec and pressing speeds up to 16 mm/sec slash production time.

Energy Efficient by Design

Reduce power consumption by 45–50% compared to conventional hydraulic press brakes.

3-Axis CNC Control

Automatic, fast, and accurate back gauge for repeatable, high-precision bends.

Operator-Friendly Interface

CybTouch 8PS Controller by CYBELEC Switzerland — intuitive, visual, and powerful.

Ultra-Silent Operation

Smooth, low-noise machine performance enhances the working environment.

Key Features That Set It Apart

Precision Automation (Y1, Y2, X)

- Servo-hydraulic closed-loop control

- ±0.01 mm repeatability for consistent bend angles

- Auto-adjusting back gauge for high-speed material handling

Energy-Saving Performance

- Smart hydraulic system reduces idle energy draw

- Stable oil temperature = steady pressure and consistent results

- Lower oil volume required = reduced heat and maintenance

Heavy-Duty Build

- IS:2062 grade steel frame, ultrasonically tested

- Machined on floor boring machine for single-reference alignment

- 12-point roller bearing guided upper beam — minimal deflection, high rigidity

Smart CNC Controller

- CYBELEC touchscreen interface (CybTouch 8PS)

- Easy programming of sequences and angles

- Designed for operators of all experience levels

Sheet Handling & Tooling Flexibility

- Quick-release punch clamps

- Front sheet supports with LM guides

- Ball screw–driven back gauge for smooth, silent travel

Applications Across Industries

- Automotive : Brackets, chassis panels, body structures

- Aerospace : Lightweight alloys and titanium with exact tolerances

- Construction : Steel cladding, architectural elements, structural parts

- General Fabrication : From prototypes to full-run production with confidence

This machine fits effortlessly into any fabrication floor — small or large.

Outperforms the Competition

Compared to PrimaPress, ADHMT, KRRASS, and ACCURL, the RG MAXX BEND Series offers:

- Up to 50% energy savings — more output with lower cost

- Superior build quality — rugged frame and precision machining

- Faster speed-to-output ratio — reduced cycle times

- Custom-built configurations — designed to suit your specific job requirements

All backed by Rajesh CNC’s trusted service and manufacturing expertise.

Additional Advantages

- Low Maintenance Design — Built for long intervals between service

- Tool Compatibility — Works with a variety of dies and punches

- Smart Diagnostics — Monitors machine health to avoid breakdowns

The RG MAXX BEND Series isn’t just efficient — it’s designed to stay efficient over years of use.

Why Fabricators Trust Rajesh CNC

- Advanced Engineering Legacy — Decades of CNC experience with global reach

- Tailored-to-Order Machines — Tonnage, size, and features that match your operations

- Reliable After-Sales Service — Installations, training, and full technical support

- India-Made. Globally Trusted. — Serving industries in over 15 countries

Technical Characteristics

- Hydraulic System : HOREIBGER - HAWE makes a hydraulic system with a servo valve and a prefill block

- X Axis : 650 mm travel with AC servo drive and ball screw movement

- R Axis : Automatic / Manual adjustment, 200 mm travel (Selected Axis Option)

- Z Axis : Manual adjustment with linear guide movement (Selected Axis Option)

- Front Sheet Support Arms : Mounted on LM guide – sliding type (2 Nos.)

- Backgauge Fingers : 2 Nos.

- Anti-Deflection System : CNC anti-deflection table with point-to-point adjustment using European technology

- Electrical Panel : Schneider make electrical panel with integrated safety features and servo drive

- Axis Motor Type : Servo motor with inbuilt cooling fan (Auxiliary Axis)

- Tooling : Standard Tooling

Controller Options

- CYBELEC : CYB Touch 8PS / 12PS / 19PS

- STEP AUTOMATION : ROCK 12 PLUS / 15 PLUS / 17 PLUS