Heavy Duty Hydraulic Shearing Machine

Heavy Duty Hydraulic Shearing Machine

Unlock precision, productivity, and performance with our advanced NC Shearing Machine — built for demanding fabrication environments. Whether you’re processing thin sheets or thick plates, our machines deliver consistent, high-quality results with every stroke. Engineered to integrate seamlessly into your workflow, they help you cut faster, cleaner, and more efficiently.

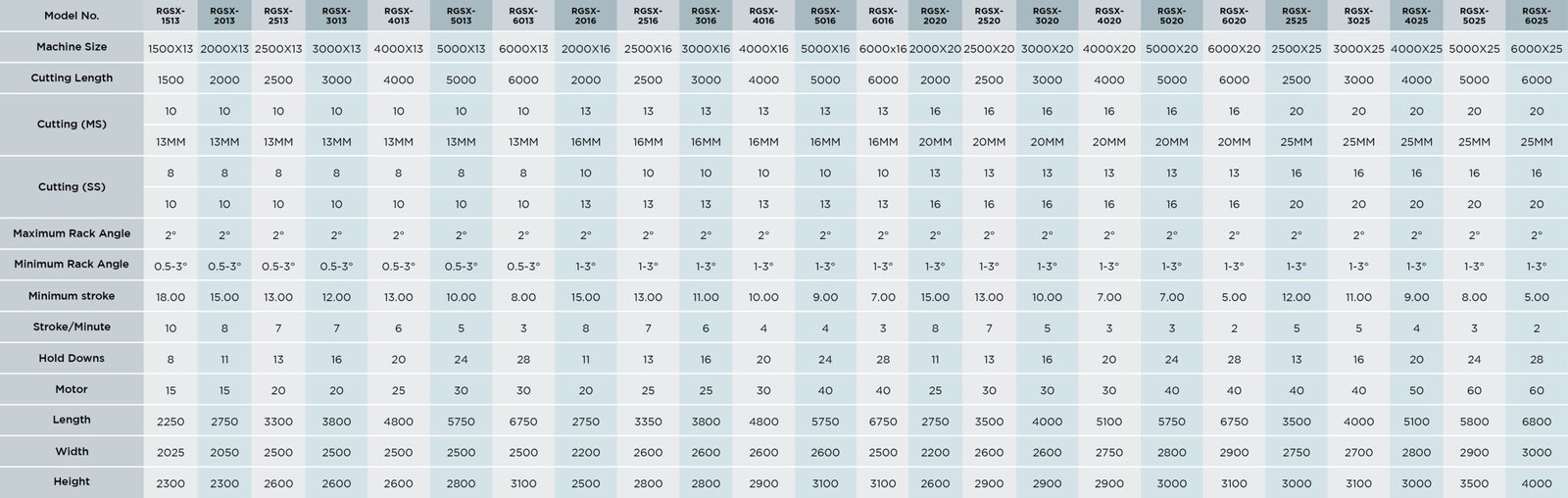

Technical Specification

Why Choose Rajesh NC Shearing Machines

Our NC Shearing Machines are designed for modern fabrication needs — reducing waste, boosting throughput, and ensuring operator comfort.

Precision Without Compromise

Clean, burr-free cuts using NC-controlled back gauge and variable rake angle design.

Versatile Across Applications

Works seamlessly across mild steel, stainless steel, aluminum, brass, and copper.

Durability Built In

Rugged structure with hardened ball screws and LM bearings for long-term reliability.

Smart Controls

Intuitive NC controller enables easy programming of stroke, back gauge, and stroke count.

Custom Configurations

Tailored builds to suit your specific materials, volume, and shop layout.

Key Features at a Glance

Variable Rake Angle Design

- Automatically adjusts based on sheet thickness.

- Clean cuts at low rake angles for thin sheets.

- Maximum capacity at higher angles for thicker material.

- Reduced distortion, higher finish quality.

Advanced NC Controller

- Quick programming for back gauge and stroke.

- Built-in stroke counter and job memory.

- Digital interface from top global brands.

High-Precision Back Gauge

- Repeatability of ±0.1 mm for batch consistency.

- Fast, servo-driven positioning with timer belt.

- Hardened ball screws + LM guides for smooth motion.

- Auto retraction avoids jamming.

Rugged Construction

- Fabricated from IS 2062 grade steel with ultrasonic testing.

- Low-noise hydraulic system with compact manifold design.

- Pre-calibrated blade gap settings for easier maintenance.

Smooth, Silent Operation

- Noise-dampened hydraulics for operator comfort.

- Effortless cutting motion, even in long shifts.

Applications

Our NC Shearing Machines are trusted across critical industries:

- Automotive : Precision body panels, brackets, and substructures.

- Construction & Infrastructure : Steel plates for frames, cladding, and roofing.

- Aerospace : Lightweight metals like aluminum and titanium, cut with accuracy.

- General Fabrication : Prototypes, one-offs, or high-volume jobs.

- Shipbuilding : Thick marine-grade steel handling with ease.

- Electrical & Electronics : Clean cuts for panels and enclosures.

Benefits That Add Real Value

- Increased Productivity : Faster setup and cutting cycles with NC automation.

- Exceptional Cut Quality : Minimized burrs and post-processing.

- Cost-Effective Operation : Energy-efficient design and reduced material waste.

- Operator-Friendly : Easy-to-use NC interface reduces training time and fatigue.

- Scalable Systems : Modular options for growing demand.

- Sustainable Cutting : Designed to reduce material loss and energy usage.

Why Partner with Rajesh CNC

- Decades of Expertise : Trusted engineering for Indian and global markets.

- End-to-End Support : Installation, training, servicing — handled by professionals.

- Value-Focused Pricing : High-end tech, priced right.

- Innovative Engineering : We stay ahead so your shop can too.

- Tailored Delivery : Machines configured to your exact needs.

How to Select the Right Machine

- Match capacity to your material type and thickness

- Consider automation for high-volume needs

- Ensure your NC controller is future-ready

- Prioritize build quality and post-sale support

- Factor long-term savings into ROI

Maintenance Tips for Peak Performance

- Keep blades sharp and aligned

- Lubricate moving parts regularly

- Clean surfaces and clear debris

- Monitor hydraulics for leaks or contamination

- Schedule timely servicing for preventive care

Features

Standard Accessories

- Hydraulic Variable Rake Angle With Dual Cylinder

- Four Edge Interchangable Shearing Blade

- Right Angle Squaring Arm 1000 Mm Long

- Front Sheet Support Arm ( Length 600 Mm )

- Backguage Movement By Lead Screw With Handle

- Manual Blade Clearance Adjustment

- Sheet Claming Automatic Hydraulic Type

- Power Saving Hydraulic Power Pack Unit

- Heavy Duty Fabricated Backguage

- Front Table With Transform Ball For Easy Sheet Movement

Backgauge Modification

Option: Nc Control Features

- Backgauge Movement By Ball Screw

- Backgauge Driven By Servo Motor

- Backgauge Retract System With Auto Length Adjust

- Backgauge Moving By Belt Mechanism

- 100 Programming Features

- Thickness Angle Adjust By Controller With Micro Accuracy

- Plc System Programable /auto Cutting Length Setting By Controller

- Manual/single Stroke /auto Cycle Programming

Advanced Features (Optional)

- Photo Safety Finger Guard

- Frontroller Sheet Support

- Pneumatic Type Back Sheet Support

- Auto Blade Clearance Adjust

- Heat Exchanger (For Oil Cooling )

- Individual Backguage Stopper (Left & Right)