Blog

Power Press Machines in Gujarat

Looking to boost your manufacturing efficiency? Power Press Machines in Gujarat offer precision, speed, and versatility for various industries. Enhance your production with these cost-effective tools that ensure high-quality results and significant cost savings. Discover how Power Press Machines can transform your business today!

Unlock Efficiency with Power Press Machines in Gujarat

Contents

- 1 Unlock Efficiency with Power Press Machines in Gujarat

- 2 Understanding Power Press Machines

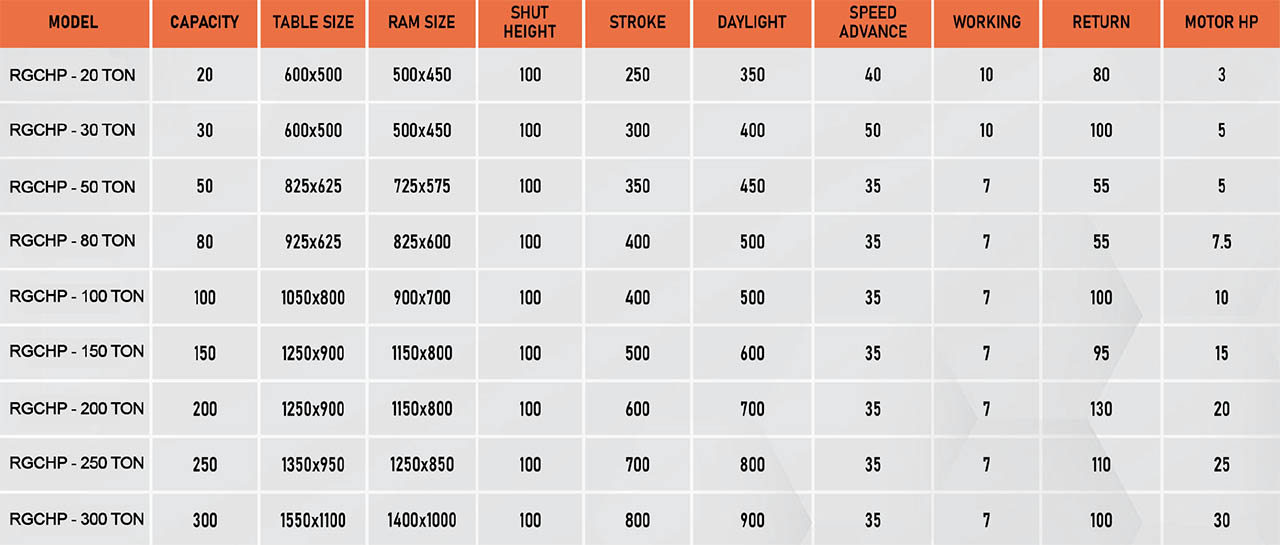

- 3 Technical Specification

- 4 The Role of Power Press Machines in Modern Manufacturing

- 5 Advantages of Using Power Press Machines

- 6 Applications of Power Press Machines

- 7 Maintaining Your Power Press Machine

- 8 Future Trends in Power Press Machines

- 9 Conclusion

In the bustling industrial landscape of Gujarat, Power Press Machines have become essential for efficient manufacturing. As businesses strive for precision and productivity, these machines play a crucial role in various sectors, from automotive to electronics. Here’s a deep dive into how Power Press Machines are revolutionizing industries in Gujarat.

Understanding Power Press Machines

Power Press Machines are versatile tools used to shape or cut materials using high pressure. They are instrumental in performing tasks like stamping, punching, and pressing. These machines use a combination of mechanical force and hydraulic power to achieve desired results, making them indispensable for high-volume production processes.

Technical Specification

The Role of Power Press Machines in Modern Manufacturing

In Gujarat, Power Press Machines are not just equipment; they are the backbone of many manufacturing processes. Their ability to handle large volumes of work with precision makes them vital for industries that require consistent and accurate production. From creating components for machinery to crafting intricate parts for electronics, Power Press Machines ensure that every piece meets stringent quality standards.

Advantages of Using Power Press Machines

- Increased Production Efficiency: Power Press Machines can significantly enhance production speed and efficiency. Their high-speed operation allows manufacturers to produce large quantities of parts in a shorter time, meeting the demands of fast-paced markets.

- Precision and Consistency: One of the standout features of Power Press Machines is their ability to deliver precise and consistent results. This precision is crucial for industries that require exact measurements and uniformity in every product.

- Cost-Effective: By automating repetitive tasks, Power Press Machines reduce the need for manual labor, which can lead to cost savings in the long run. Their efficiency also minimizes material waste, further contributing to cost-effectiveness.

- Versatility: These machines are designed to handle a variety of materials and processes. Whether you’re working with metal, plastic, or other materials, Power Press Machines can be adapted to meet different production needs.

Applications of Power Press Machines

Power Press Machines find applications across a range of industries in Gujarat:

- Automotive Industry: In the automotive sector, these machines are used for manufacturing components like brackets, panels, and gears. The precision of Power Press Machines ensures that each part fits perfectly, which is crucial for vehicle performance and safety.

- Electronics: For the electronics industry, Power Press Machines play a role in producing small, intricate parts such as connectors and housings. Their ability to handle delicate materials without compromising quality is essential in this field.

- Construction: In construction, Power Press Machines are used to create various metal components and fittings. Their robust build and reliability make them suitable for handling heavy materials and high-pressure tasks.

- Consumer Goods: From appliances to tools, Power Press Machines contribute to the production of numerous consumer goods. Their versatility allows manufacturers to produce a wide range of products efficiently.

Maintaining Your Power Press Machine

To ensure that your Power Press Machine operates at its best, regular maintenance is essential. Here are some tips for keeping your machine in top condition:

- Routine Inspections: Regularly inspect the machine for signs of wear and tear. Check for any loose or damaged parts and address issues promptly.

- Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent excessive wear. Follow the manufacturer’s guidelines for lubrication schedules and types of lubricants.

- Cleaning: Clean the machine regularly to remove debris and prevent buildup that can affect performance. Ensure that the machine is turned off and properly cooled before cleaning.

- Professional Servicing: Schedule periodic servicing by a qualified technician. Professional servicing can help identify potential problems early and ensure that the machine remains in optimal working condition.

Future Trends in Power Press Machines

As technology continues to advance, Power Press Machines are evolving to meet the changing needs of the industry. Innovations such as digital controls and automation are enhancing the capabilities of these machines, making them more efficient and user-friendly. In Gujarat, staying ahead with the latest technology can provide a competitive edge in the manufacturing sector.

Conclusion

Power Press Machines are more than just equipment; they are key drivers of efficiency and productivity in Gujarat’s manufacturing landscape. Their ability to deliver precision, consistency, and cost-effectiveness makes them invaluable across various industries. By investing in high-quality Power Press Machines and maintaining them properly, businesses can ensure long-term success and competitiveness in the dynamic market.

Read About: Shearing Machines in Gujarat

Please visit our official Instagram Page for updates from us.

For More details about our Products, you can Contact Us.